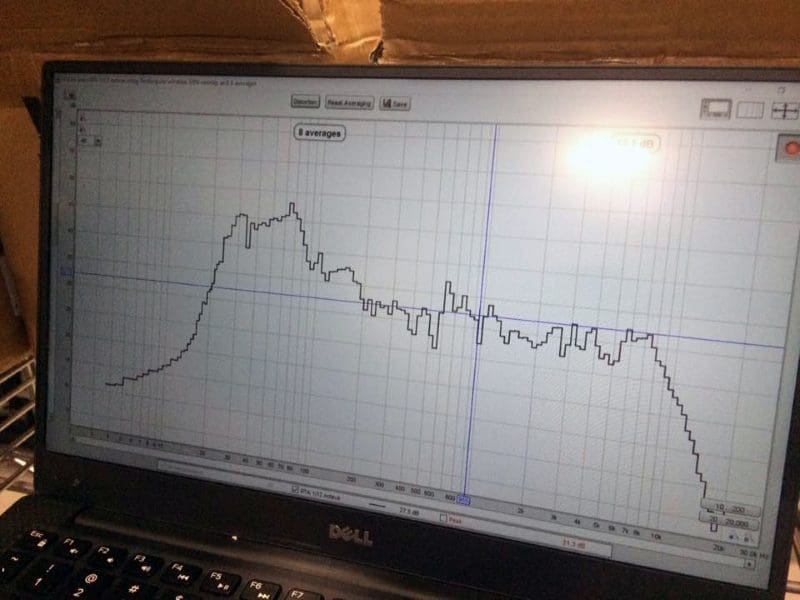

A while back, we looked at how some car audio speakers and subwoofers change in performance after they’ve been broken in. We analyzed how the Thiele/Small parameters of a sample subwoofer changed after being played for many hours. What we didn’t clarify adequately in that article was whether or not speakers had to be broken in before use.

Parts of a Speaker or Subwoofer

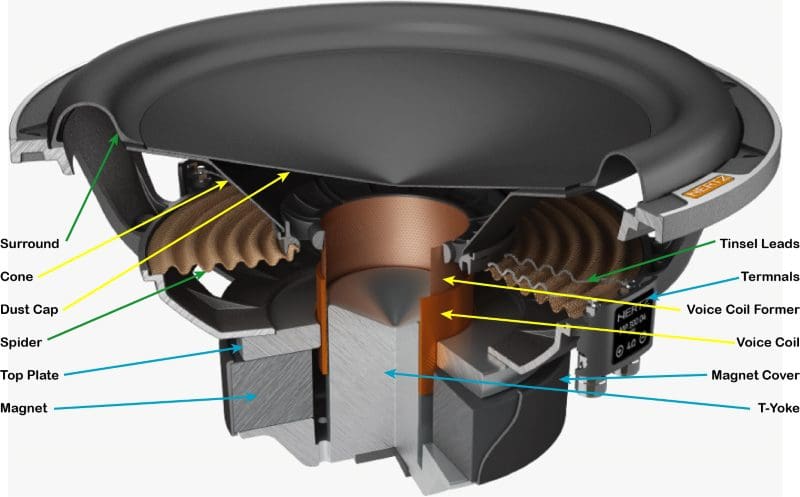

Let’s start with a look at the basic parts of a speaker or subwoofer. We’ll use this awesome cutaway drawing of a Hertz Mille subwoofer to see what parts move and understand what changes when the driver “breaks in.”

I labeled the subwoofer parts that don’t move in light blue and those that move a lot in yellow. The components that attach the moving parts to the stationary parts are labeled with green arrows. The moving parts are static relative to each other. Therefore, they shouldn’t flex or deform as they travel forward and rearward. Regarding parts that might change in compliance as the speaker is used, all we need to concern ourselves with are the spider and the surround.

The job of the surround is primarily to keep the top of the cone centered in the basket and to provide a flexible joint that will keep any sound produced on the front of the speaker cone from mixing with the sound coming from the rear. In most car audio speakers, the surround is made of foam or rubber. However, some high-efficiency P.A.-style speakers use a pleated fabric as a surround. Generally, surrounds don’t typically change in compliance over the speaker’s life, except when a foam surround dries out and fails.

Now we get to the spider. This is the primary component that controls cone motion. In no uncertain terms: the spider is a spring. The Oxford English Dictionary defines spring as “a resilient device, typically a helical metal coil, that can be pressed or pulled but returns to its former shape when released, used chiefly to exert constant tension or absorb movement.” If you push (carefully) on the cone or flow current through the voice coil, the cone will move. When you remove that force on the cone assembly, the cone returns to its rest position.

The spider used in a speaker differs from that helical metal coil spring in a pen or the suspension of your vehicle because it’s made from woven materials like cotton, cotton and polyester, rubber, acrylics or an aramid fiber (Kevlar or Nomex). The spiders made from woven materials (all but the rubber) have been impregnated with a resin to increase their stiffness. Spiders are designed with linear or progressive rolls to change their compliance at different excursion levels. Likewise, the thickness of the threads used in the weave and the amount of resin added can significantly change the compliance.

The diameter of the spider relative to the diameter of the opening in its center for the voice coil former also plays a role in its resistance to motion and effort to bring the cone assembly back to its resting position. From a transducer design perspective, the spider is a crucial component in determining the Thiele/Small parameters of a transducer and how it will operate. A stiff spider may result in a very high-Q design that rings and oscillates around the resonant frequency, whereas a compliant spider might have a low Qms that brings the cone back to rest gracefully to produce a nice, tight sound.

When the cone moves forward or rearward, the space between the rolls in the spider elongates. If the cloth is heavily doped with resin, you may even hear a slight cracking or crinkling sound the first time you push on the cone manually. This stretching of the woven material and resin will reduce the compliance of the spider. This change causes the Thiele/Small parameters to shift and can yield a change in the driver’s frequency response.

Breaking In Speakers vs. an Engine in a Vehicle

There is a common belief in the automotive industry that new car and truck engines need to be broken in gently for them to last a long time. The story goes that the pistons’ compression and oil control rings need to seat or bed themselves into the cylinder walls. Supposedly, the break-in process increases compression. Some flat tappet camshafts do need a proper break-in process at higher engine speeds to ensure that the components are lubricated properly.

What is massively important to engine longevity is making sure the engine has warmed up adequately before you put your foot to the floor. If the oil isn’t warm and flowing properly through every part of the engine, metal-on-metal contact may cause premature wear. At the very least, cold oil doesn’t flow as easily, and the engine will waste more energy trying to operate. Nevertheless, always follow the manufacturer’s suggestion for break-in to maintain your warranty.

Now, back to our speaker. Depending on the materials used to construct the spider, it might need some time to stretch into what would be considered its final operating state. If it’s stiff when new, it might soften or relax after some play time at high volume levels. If you are gentle and don’t play the speaker loudly, nothing will ever stretch, will it? When I’m setting up to review a speaker, I apply a low-frequency signal to the driver to exercise the suspension. I usually let the speaker play for at least five hours and sometimes 10. Small drivers might only see 3 or 4 watts of power to provide sufficient excursion. A subwoofer might need 25 watts to get the cone going.

What’s Best for My New Car Audio Speakers?

If you’ve purchased new speakers or a subwoofer for your car or truck, the first thing you need to know is that you can enjoy them right away. If they do need some break-in time, make it happen. Turn up the volume and get things stretched and into their optimal operating condition. The only way to know if a speaker design will change (from a consumer perspective) is to measure its parameters when brand-new, then again after many hours of playing. If they change, then you’re good to go. If they didn’t, you’re still good to go. See a pattern?

Suppose you’re having an audio system installed that will be calibrated with a digital signal processor. In that case, changes to suspension compliance of a speaker or subwoofer may affect the system’s frequency response. Have the system installed, get it calibrated, then enjoy it. Schedule an appointment to have the calibration checked after a few months of play to see if it needs a tweak.

Do You Need To Break In New Car Audio Speakers?

The question of whether you have to break in new car audio speakers remains. Is it necessary to break them in slowly? No. Is it necessary to break them in for them to last? No. Is it essential to break in speakers to make them sound their best? Maybe. This last question depends on the design of the speaker. More specifically, the compliance of the spider may change after many hours of being played. Thankfully, it’s likely that the speaker will only sound better and better.

One of the best ways to upgrade the performance of your car audio system is to have new speakers installed. Drop by your local specialty mobile enhancement retailer today to find out about the speaker upgrade options for your vehicle.