Not long ago, I wrote an article about fuses in car audio systems and some of the steps I took at a previous employer to test them. In part of that testing, I also dissected a few circuit breakers to learn how they worked and whether they were a good option as an overcurrent protection device in a car audio system. Immediately upon opening one, I was turned off. I remain so to this day. Curious? Let’s take a look at why.

What Is a Car Audio Circuit Breaker?

Car audio circuit breakers are resettable overcurrent protection devices. When too much current passes through a fuse, the link overheats and fails. The fuse is left in a permanently open state. On the other hand, a circuit breaker can be tripped many times. That’s its biggest benefit. If there is an accident with a wire and the circuit breaker opens, it can be closed once the fault is cleared.

How Do Circuit Breakers Work?

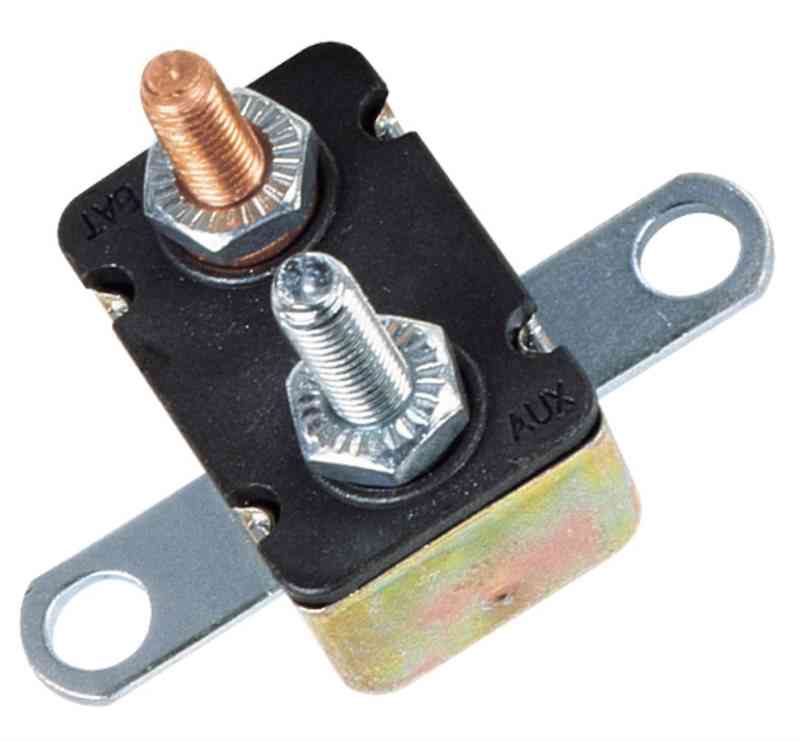

A circuit breaker has two terminals. In some circuit breakers, one terminal is labeled as specifically for the battery and the other as the output to the load. With that said, a current flowing in one direction or the other produces the same amount of heat. It shouldn’t matter which way the breaker is wired, but always heed the manufacturer’s instructions. Electrical current flows into the breaker and passes through a bimetallic plate to a contact that is touching a contact attached to the breaker’s output.

The key to the protection this device offers is the bimetallic plate or, more accurately, spring. When this spring heats up, it starts to bend, just like the spring in an old-fashioned mechanical thermostat. The spring is made of two metals that are bonded together. The metals have significantly different expansion rates, so the spring bends as it gets warmer. Then, as it reaches a certain shape, it pops open. The action is similar to those rubber popper toys or a domed jar lid – like you’d find on a jar of baby food. This sudden action results in a decidedly abrupt opening of the contacts and helps to minimize any arcing or sparks that might take place if the contacts were opened slowly.

Two types of circuit breakers are commonly used in automobiles: auto-resetting and manual-reset circuit breakers.

Once the spring cools below a specific temperature in an auto-resetting circuit breaker, it snaps back into its closed position, and the contacts reconnect the circuit. If the fault still exists, the spring will heat up again and open, and the cycle will repeat. Ultimately, if there is an overcurrent condition, it’s safer for the circuit to remain open so a professional installer can diagnose it.

Next, we have the manually resettable circuit breaker. These protection devices work the same way in terms of their contacts and a bimetallic strip, but once they open, they stay open until a small lever is turned to close them manually. In short, there’s some added geometry and component placement in the design that prevents them from reclosing automatically. The benefit of most manual breakers is that there’s a button you can press to open the breaker to disconnect the load from the power source.

A Look Inside a Circuit Breaker

I purchased a few inexpensive circuit breakers to give you a look inside these devices and to perform some testing against fuses. We’ll do the testing in another article, so let’s dive inside.

This 100-amp breaker is typical of what you’d see used to protect a power wire connected to the battery in a car audio system. Cutting open this breaker reveals the parts you see in the image below.

Looking at the inside of this breaker shows us the clear reset lever and its spring, along with the bimetallic spring that’s responsible for opening and closing the contacts. When the bimetallic spring heats up and pops open, the small coil spring attached to the clear reset level shaft pulls it to the open position and moves the red lever on the top of the case.

We find a pair of contacts underneath the spring that are connected to the Aux terminal on the body. The threaded post at the top of the image is connected to the input terminal on the exterior of the breaker.

Why I’m Not Too Fond of Circuit Breakers

There are three reasons I’m not a fan of circuit breakers – and there’s one reason they can be a good solution.

Let’s start with their benefit. They can be opened manually. So if your installer wants to work on your audio system, the breaker can be opened by pushing a button. It’s quick and easy and doesn’t require any tools.

On the downside, my first concern about circuit breakers is how they pass current. If you look at the small domed button in the last two images, all the current has to pass through these contacts. As they are dome-shaped, the contact area will be tiny. So it’s my hypothesis (and one I’ll test in a future article) that there is more voltage drop across a circuit breaker than there is with a fuse.

Second, and this is an extension of the first – when the contacts open, a large electrical arc will be created. I was pleased that this breaker didn’t show any damage when I took it apart, but that hasn’t always been the case. The first breaker I ever disassembled showed signs of significant arcing on the terminals. This arcing will reduce the quality of the contact area and increase resistance.

Lastly, there is a chance that a circuit breaker may weld itself closed if too much current passes through it before the bimetallic spring can heat up and open the contacts. With the terminals spot-welded together, it can’t protect the power source (alternator and battery) from a short circuit.

Make Sure Your Vehicle Is Protected

Whether you choose a fuse or a circuit breaker, having there’s an overcurrent protection device in your electrical system is essential. Talk to the shop and installer you’re working with to determine what they will be using on your amplifier or second battery installation before work begins.