You should be aware that copper-clad aluminum wire is the least-preferred option for connecting an amplifier to your vehicle’s battery or alternator. Copper-clad aluminum wire has more resistance for a given diameter than an all-copper cable. As a result, it wastes precious voltage and transforms it into heat when it could be allowing your amplifier to make more power. Why do many high-quality speakers and subwoofers use CCAW in their voice coils? Read on for an explanation.

Speaker Parameters and Frequency Response

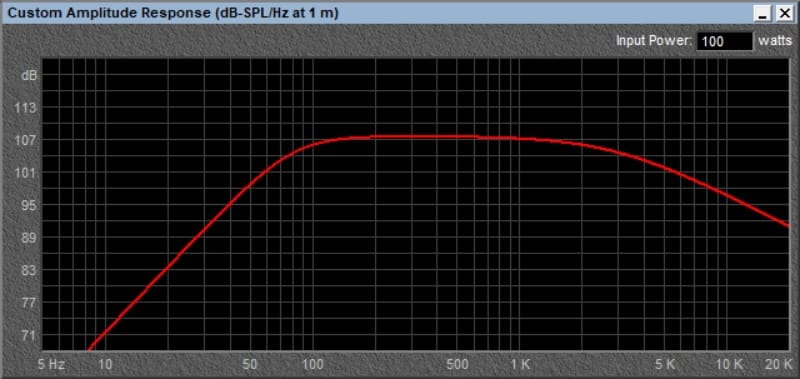

No single specification can describe how a speaker or subwoofer will perform. To create a product that delivers flat response through its designed operating range, speaker design engineers need to balance several factors to achieve their design goals. These factors include the speaker’s size, resonant frequency, cone mass, suspension compliance, inductive properties and target power-handling capabilities.

The graph above shows the predicted frequency response of a Rockford Fosgate T4652S woofer in red. The low-frequency response and efficiency are based primarily on the driver’s suspension compliance and the cone’s mass. The speaker’s voice coil inductance is what determines the high-frequency roll-off.

The yellow trace is the same driver, with 5 grams added to the moving mass value. As you can see, the driver is a few decibels louder at frequencies below 80 Hz and a few decibels less efficient above that frequency. The decrease in efficiency happens because the assembly is more challenging to accelerate. A second change is that the resonant frequency is lower.

The green trace is the same Rockford Fosgate driver simulation with 5 grams subtracted from the moving mass. As expected, the driver would produce less bass but be more efficient at higher frequencies.

Speaker engineers work hard to balance all these criteria to produce a product that will blend well with your subwoofers and offer good efficiency. If we take a given speaker design and add mass to the cone assembly, we increase how much bass it can produce but decrease its efficiency. Likewise, reducing the mass results in an increase in the speaker’s efficiency and a reduction in bass output.

Voice Coil Impedance Matters

Another factor that’s crucial to speaker design is voice coil impedance. When an engineer sets out to create a speaker, one of the target specifications will be for the driver to have a specific nominal impedance. Designing a speaker with a 2-ohm impedance doesn’t work if it’s intended for use with an amplifier designed for 4-ohm loads.

Speaker designers have different options for voice coil wire diameter to change the impedance of the winding. More wire means more impedance. Smaller diameter wire also increases the impedance.

However, they must create a voice coil winding tall enough to ensure that the driver remains linear at its excursion limits. The voice coil winding must also be tall enough to handle the heat it will dissipate. Dainty, small-diameter windings, like you’d find in entry-level speakers, don’t have enough physical size to dissipate large amounts of heat. When they get hot, the varnish on the wire melts, and the windings may short together or unravel. The result is a permanently damaged woofer. As such, larger-diameter windings, which use more wire, are necessary.

Another way to increase thermal power handling is to add additional layers to the voice coil. You may have seen four- and six-layer voice coils in some high-power subwoofers. These designs can handle more power than a two-layer coil. However, more copper means more resistance and more mass. The result of these mass increases is decreased speaker efficiency.

The Benefits of CCAW Voice Coils

Speaker design engineers often turn to CCAW to add resistance to a voice coil winding. For example, we might want a speaker to have a nominal impedance of 4 ohms. As such, the voice coil will require a specific amount of copper wire to hit that impedance. The designer could also use 1.62 times as much CCAW of the same diameter wire to reach the same impedance. We also want the voice coil assembly to hit a target mass to work with the cone, dust cap, spiders and surround to achieve a target mass. The choice of material for the voice coil former is also a variable.

CCAW has less mass per unit length than all-copper conductors. It also has more resistance per unit length.

Let’s look at the mass of a CCAW conductor that is 25% copper and 75% aluminum. First, we know copper has a specific gravity of 8.96. Aluminum has a specific gravity of 2.7. If we combine these in a ratio of three parts aluminum to one part copper, we have an alloy with a specific gravity of 4.265. That’s just under half the specific gravity of copper alone. For the sake of simplicity, you can generalize that CCAW weighs half as much as copper. The actual mass depends on the ratio of copper to aluminum, which varies significantly from each supplier.

Next, let’s look at resistance the same way. For a given area, copper has a resistance of 1.7×10-6 ohms per centimeter. Aluminum’s resistance is 2.7×10-6 ohms per centimeter. Most CCAW wiring offers 0.62 to 0.64 of the conductivity of pure copper.

So, a speaker designer can increase the length of the conductor in a voice coil using CCAW wire to hit a target size and impedance. They can switch to CCAW wire to decrease the mass of a voice coil assembly.

There’s No Correlation Between Amplifier Wiring and Voice Coil Design

So the next time you hear someone put down a speaker design because it features a CCAW voice coil, remind them that speaker design and power delivery goals are unrelated. When powering an amplifier, we want the lowest resistance wires possible. We want the lowest resistance wires possible when connecting a speaker or subwoofer to an amplifier. As such, we should use large-gauge, all-copper wiring. When it comes to speaker design, the goals are very different. The engineer wants a voice coil with a specific length, impedance and mass. A conductor with more resistance and less mass per unit length is one of the variables the designer can change to meet their goals.