When you install or upgrade a car audio system, the efficacy and reliability of wire connections can significantly impact its performance, longevity, and safety. Each method—whether soldering, crimping, twisting and taping, or using connectors—has unique benefits and challenges. Moreover, understanding the details of each approach helps ensure the best results for your specific installation needs.

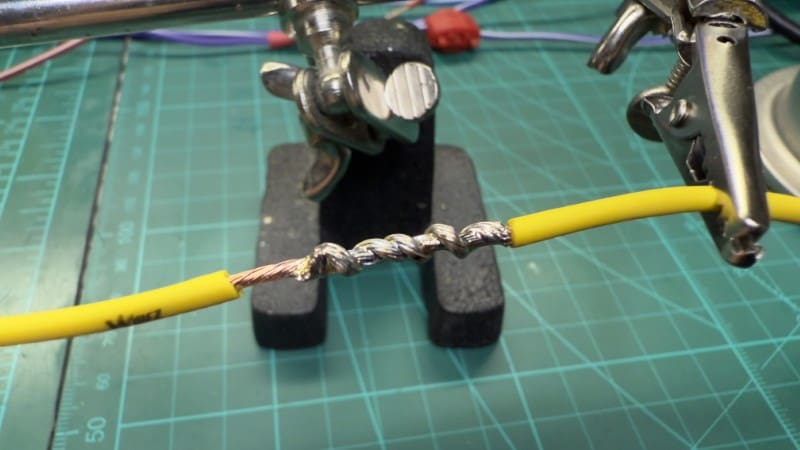

Soldering: A Reliable, Professional Option

Soldering involves melting a filler metal to create a permanent bond between two wires. Many professionals consider this method the gold standard for wiring because of its durability and electrical efficiency.

How It Works

The soldering uses a soldering iron to heat two wires. Once hot, solder is melted into the connection. The result is a strong electrical and mechanical connection. Once the solder cools, it solidifies, forming a durable, airtight bond.

Advantages

- Reliability: The soldered joint is secure and resists loosening, even in high-vibration environments.

- Excellent Conductivity: Soldered connections provide seamless electrical transfer, minimizing signal loss and interference.

- Longevity: Properly soldered wires resist corrosion and oxidation, ensuring a stable connection.

Disadvantages

- Skill Requirement: Soldering demands practice and precision to achieve clean and effective joints.

- Time-Consuming: Compared to other methods, soldering often requires more time for preparation and execution.

- Permanence: Modifying a soldered connection can be difficult without desoldering tools.

- Wire Hardening: Adding too much solder to a braided wire makes it brittle, increasing the chance of failure.

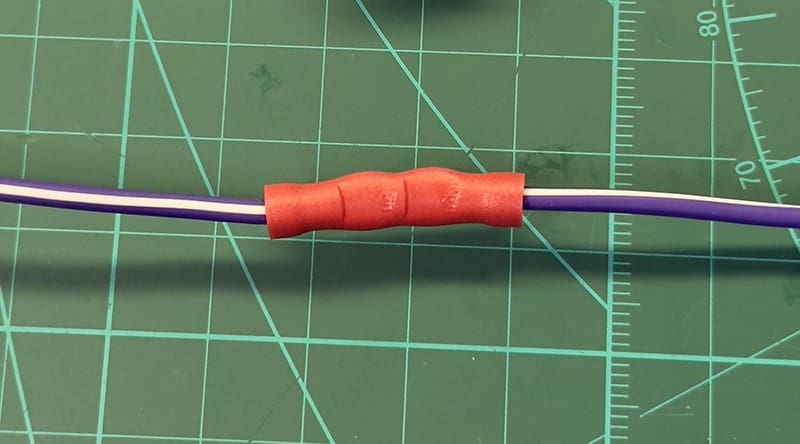

Crimping: A Quick and Effective Solution

Crimping uses mechanical force to compress a connector onto a wire, forming a secure physical and electrical connection. This method is often popular because of its simplicity and speed.

How It Works

A crimping tool compresses the connector—such as a butt splice or ring terminal—onto the stripped end of a wire. This pressure creates a strong bond to hold the wires securely while allowing current to pass efficiently.

Advantages

- Efficiency: Crimping is fast, making it ideal for installations with numerous connections.

- Accessibility: Requires minimal training and fewer specialized tools compared to soldering.

Disadvantages

- Quality Dependency: The effectiveness of a crimped joint depends heavily on the quality of the tool, the crimping technique, and the terminal itself.

- Potential Loosening: If low-quality terminals are used, crimped connections may loosen over time, especially in high-vibration environments.

- Corrosion Risk: Without proper insulation, crimped connections can be susceptible to environmental factors like moisture and oxidation.

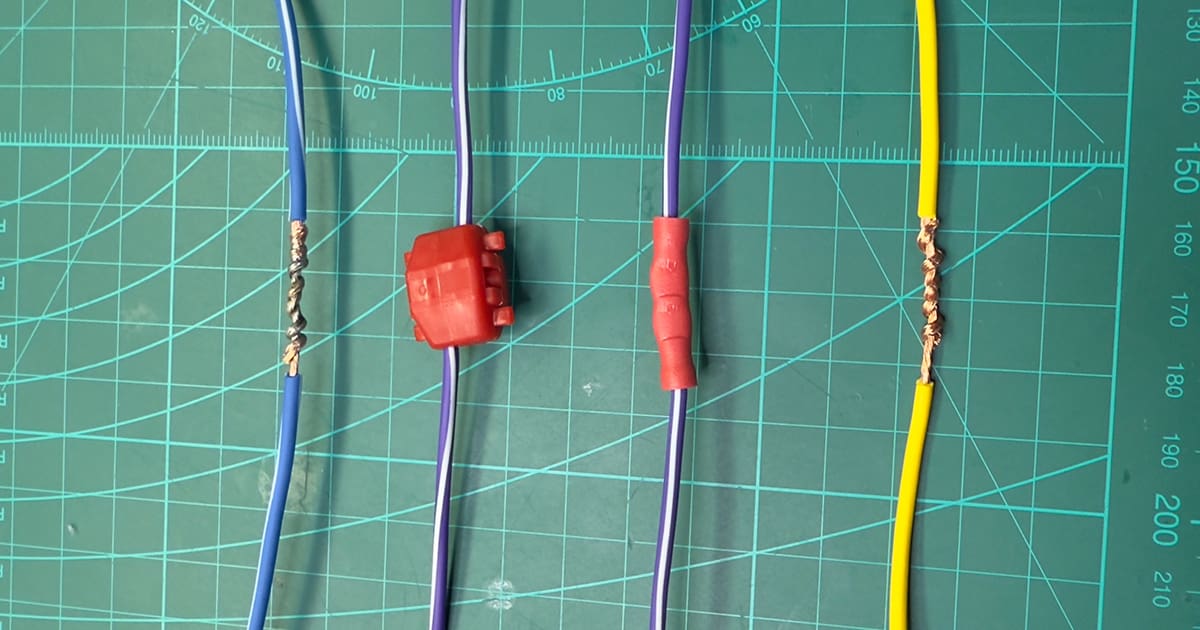

Twisting and Taping: A Basic but Risky Method

Twisting and securing wires with electrical tape is a common DIY approach. However, it lacks the reliability and safety of professional methods.

How It Works

Wires are stripped, twisted together, and covered with electrical tape to hold the joint in place and provide basic insulation.

Advantages

- Low Cost: Requires no specialized tools or materials, making it the cheapest option.

- Simplicity: The process is quick and requires minimal technical expertise.

Disadvantages

- Instability: Twisted joints can easily loosen, causing intermittent or failed connections.

- Poor Insulation: Low-quality electrical tape can unravel or degrade over time, exposing the wires to short circuits and corrosion.

- Unprofessional Appearance: The lack of a mechanically secure connection is unsuitable for high-quality installations.

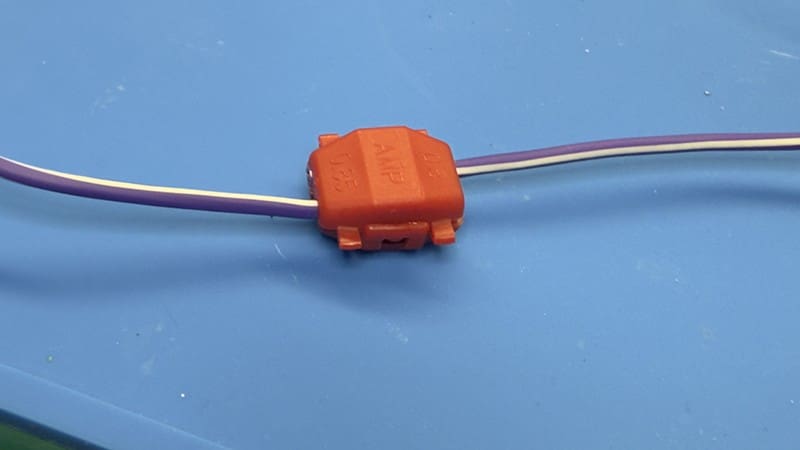

Displacement Connectors and Scotchloks™: Convenience at a Cost

Connectors, such as quick disconnects or Scotchlok™, are pre-made solutions designed for ease of use. Nevertheless, they are often employed only for temporary or low-priority connections.

How It Works

Connectors join wires by clamping or piercing the insulation. For example, Scotchloks™ use a blade to cut through the wire’s insulation and create an electrical connection.

Advantages

- Ease of Use: No soldering or crimping tools are needed; these methods are straightforward.

- Speed: Connections can be completed in seconds, making them convenient for quick fixes.

Disadvantages

- Wire Damage: If an incorrectly sized connector is used, displacement connectors can damage the conductor, weakening the wire’s integrity.

- Limited Durability: This connection method offers no protection against corrosion, making it unsuitable for many applications.

- Electrical Inefficiency: Poor wire-to-connector contact can lead to higher resistance, reducing the system’s performance.

What Wire Connection Method Is the Best?

Each wiring method has its place in car audio installations. However, your choice depends on priorities and project demands:

- For Maximum Reliability: Soldering is ideal for permanent, high-performance installations where longevity and conductivity are critical.

- For Speed and Practicality: Crimping balances ease of use and reliability for most automotive wiring needs.

- For Temporary Solutions: Twisting and taping or using Scotchloks may suffice but should not be used for critical connections.

Trust a Professional for the Best Results

Even with the best tools and techniques, achieving flawless wiring connections requires experience. Therefore, professional car audio installers have the knowledge and resources to ensure every joint meets the highest reliability and safety standards. We have done extensive testing on different wire connection methods. You can read that article here:

https://www.bestcaraudio.com/testing-15-types-of-electrical-connections/

To learn more about the wiring methods mentioned in this article, visit a qualified retailer near you.

Conclusion on Wire Connection Methods

Understanding the nuances of each wiring method is essential for achieving a successful car audio installation. Whether you opt for soldering, crimping, or another approach, prioritizing quality and safety will ensure your system performs at its best for years.