We were recently at an event that was hosting a mobile audio system SPL competition. If you aren’t familiar with this sort of thing, it’s a contest to see who has the loudest stereo. We aren’t talking about cranking the dial on the factory radio. Instead, some of these folks build steel and concrete reinforced subwoofer enclosures and feed tens of thousands of watts to their subwoofers.

As you can imagine, delivering that much power requires significant electrical system upgrades. Many of these creations have multiple alternators and huge banks of batteries. If you’ve upgraded your car or truck with an amplifier that can produce hundreds of watts to your speakers, there’s a wiring upgrade called the Big Three that can improve the efficiency of your electrical system. Let’s look at what this upgrade is and why it’s a great starting point for a high-power car audio system.

How Automotive Charging Systems Work

The first thing you need to know about delivering power to your amplifier is that most of the energy will come from your alternator, not the battery. The battery is there to start the car. Once a vehicle is started, the alternator, which is mechanically driven by the engine, provides power to replenish the battery for the next start. The alternator also runs the computers, ignition system, fans and lights in your vehicle. Once you’ve started the vehicle, you could remove the battery and everything would, under normal conditions, operate just fine.

This scenario changes if you add a high-power amplifier to your vehicle. Say you have a 1,000-watt amplifier and you want to deliver that full amount of power to a few high-power subwoofers. At 13.8 volts, most amplifiers of this type will consume about 100 amps of current. If you have the engine running, headlights on and a climate control system in operation, your car or truck may be using 30 or 40 amps of current to power those systems. If the alternator is only rated to produce 80 amps, there certainly won’t be 100 amps left for your stereo.

The additional current the amplifier wants will come from the battery, albeit at a lower voltage. You will likely find that an amplifier rated for 1,000 watts at 14.4 volts can only produce about 800 watts at 12 volts without clipping the output signal and adding significant distortion.

How To Make the Most of Your Alternator

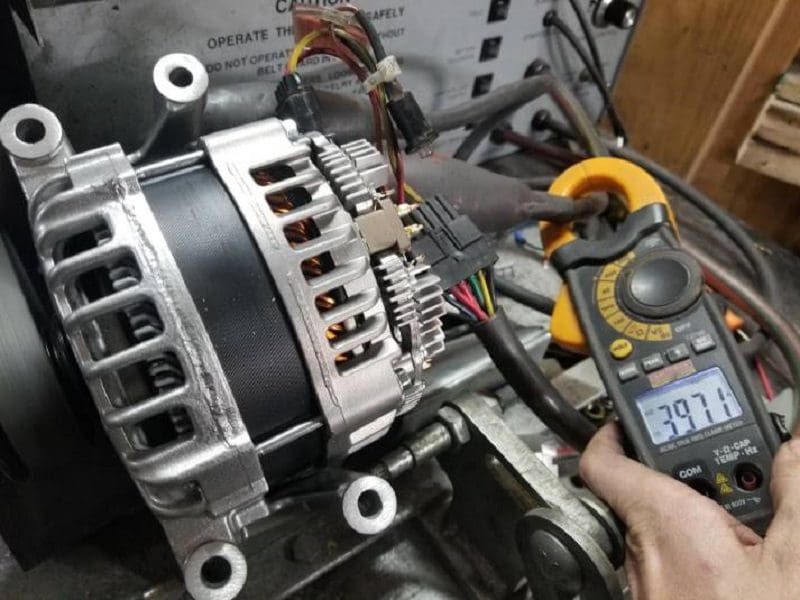

The first step in optimizing the electrical system in a car or truck is to reduce waste. In this case, waste is the power converted to heat because of resistance in cables and connections. First, have a look at your alternator and battery. How large are the wires running to and from them? Unless you have a big truck with a high-output alternator, chances are that the wiring is 4 or maybe even as small as 6-AWG.

Please make no mistake about it, the company that built your car or truck deliberately chose the smallest, lightest and least expensive wire that would allow the vehicle to function reliably. They had no intention of providing conductors that could handle two to three times what the alternator was rated for.

The Wiring Upgrades that Make the Difference

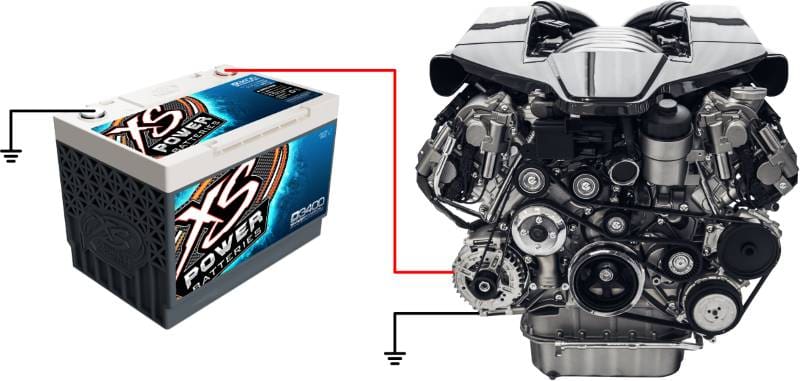

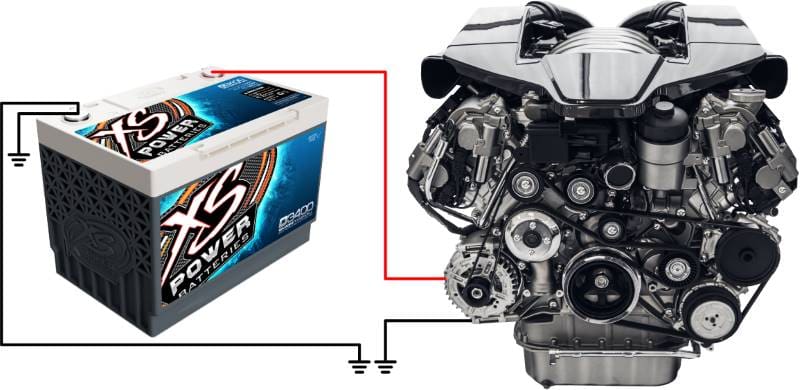

The Big Three upgrade involves adding to or replacing the existing conductors with larger, high-quality wires. The upgrades in the Big Three are:

- The run from the alternator chassis to the negative terminal of the battery.

- The run from the output of the alternator to the positive terminal of the battery.

- The ground connection from the negative terminal of the battery to the chassis of the vehicle.

Depending on your vehicle, there may be other wires that can be upgraded at the same time. For example, if there is a main power distribution box under the hood, running new wire to it can help provide more voltage to the factory-installed electrical and electronic components in your vehicle.

Another upgrade you may want to make at the same time is replacing the battery terminals. Some factory-installed terminals are notoriously flimsy. If you’re demanding significant current from the battery, then optimizing each component along the way only makes sense.

Is the Big Three Enough?

In 2012, we wrote an article about upgrading the stock electrical system wiring in modern cars and trucks. Even though it was a decade ago, new vehicles at the time were being constructed out of materials like QuietSteel and aluminum, and some companies had started using adhesives instead of spot welds to bond unibody panels together. All of these advances in vehicle assembly work against our desire to deliver large amounts of current to an amplifier, especially when we want to use the body as the ground return path.

Power delivery from the positive terminal of the alternator is as important as the ground connection to the chassis and battery. If the current can’t flow through both, you are wasting energy by transforming it into heat. Upgrading and adding grounds with the Big Three is a start. If you are serious about optimizing your electrical system, then you’ll want to add a ground wire from the battery or alternator directly to your amplifier. Back in 2012, we called this the Big Four.

Full disclosure: This wasn’t our idea. The first we heard of running a dedicated ground wire was when we were checking out Precision Power’s fleet of Chevrolet Suburban demo vehicles back in the ’90s. The topic came up again when Ford introduced QuietSteel in the F-150 vehicles, and companies were having problems with amplifiers failing because of low voltages. As a solution, JL Audio suggested adding what they called a parallel ground. This wire would connect to a conventional ground point in the rear of the vehicle and run to the battery’s negative terminal or the alternator. A benefit of the parallel ground is that it offers less resistance than a dedicated ground wire or using the chassis. As a result, current can flow through both paths, reducing the voltage drop and improving system performance.

Optimize Your Vehicle Electrical System

If you’ve purchased a high-power amplifier for your vehicle, talk to your local specialty mobile enhancement retailer about upgrading all the wiring in the electrical system. Implementing an upgrade like the Big Three or, better yet, the Big Four will allow the amplifier to produce more power and allow the system to play louder with improved reliability and efficiency.