In late September, I got a call from a friend asking if I had any connections to purchase some new fuse holders for his car. The car is a fourth-generation Toyota Supra with a single-turbo kit and an AEM stand-alone engine management system. Unfortunately, it seems the fuse holders that fed the dual Walbro 255 lph fuel pumps had failed, leaving my friend stranded on the side of the road. He called me hoping to find a high-quality solution to prevent the problem from happening again. Game on!

The Problem

Each of the fuel pumps in the rear of the car has a run of 10-AWG wire from the battery directly to a Bosch 40-amp relay that is controlled by the AEM ECU. The car runs on one of the pumps at low engine loads, then brings the second online above a preset boost level to ensure that fuel pressure remains constant under high flow demands. It seems the fuse in the holder for the main pump wasn’t making good contact with the terminals. Frustratingly, the pump ran at idle, but as soon as there was load on the engine, the resistance in the connection to the fuse limited how much current would flow, and the voltage at the pump dropped low enough that it stopped.

In short, the problem was that corrosion and repeated heat cycling had degraded the connection between the terminals in the fuse holders and the fuse.

The Solution

My friend is justifiably obsessive about the quality of each component he adds to the car. He knew that when it came to wiring, I was equally picky. So we spent some time searching the internet for a high-quality fuse holder solution that would work with the 10-AWG wiring. We settled on a pair of the Delphi Metri-Pack 630 Fuse Holder kits from CE Auto Electric Supply in Gilbert, Arizona. Tony, the owner of CE Auto Electric, is a car audio guy who’s turned his passion for proper wiring into a business supplying electrical and wiring components for cars and trucks.

The fuse holders were chosen based on three requirements. First, they had to be of high quality. Knowing that they’re a genuine Delphi part and not a clone was vital. The holder’s body is made of nylon plastic, and it includes weathertight seals around the electrical connections and the removable cap. Second, the terminals that came in the kit are tinned brass. The terminals have a built-in spring that puts pressure on the tab of the ATC-style fuse to ensure a solid connection. Lastly, we chose the fuse holders as a kit to make the wiring any length we wanted to minimize connections.

The Installation

I have a ratcheting crimper set that came with six different dies that we knew would establish secure and solid connections. I also picked up a length of all-copper 10-AWG wire from Burlington Radioactive. There is no point in guessing about the size and material content of wiring when the connection absolutely has to be reliable. Lastly, I raided one of my parts storage cabinets in the garage for butt connectors, ring terminals and some adhesive-lined heat shrink tubing.

As you can imagine, the rest of the project was simple. We cut out the old fuse holders, extended the wires from the vehicle’s rear and installed the new Delphi holders. It took a couple of hours as we were obsessively methodical about each step of the process. First, we made sure each connection was perfect and searched for an ideal mounting location for the fuse holders.

What Is Your Point?

By now, you have to be asking about the purpose of this overly detailed story about fuses. Don’t fret; there is a point!

Electrical connections are crucially important to the reliability of your vehicle and the performance of any upgrades you install. Having been the product development manager for a car audio wiring and accessory company in the past, I concern myself with these details a little more than most.

I can’t even begin to count the number of times I’ve seen my car audio friends post pictures of melted fuse holders, stiffening capacitors and battery terminals on social media. These posts usually contain at least a dozen comments about the wire being copper-clad aluminum instead of pure copper. While that might be a contributing factor, the reality is that there was a loose connection that created a LOT of heat.

Let’s Test It!

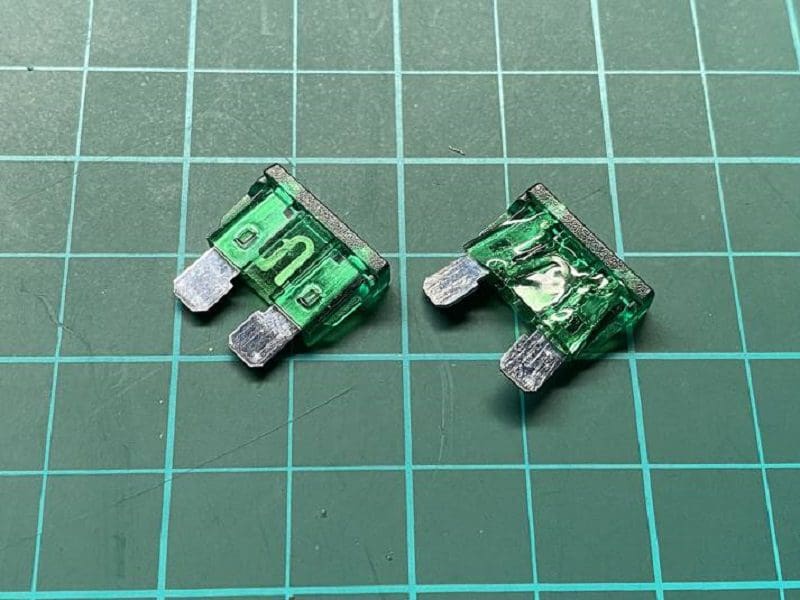

How about a bit of a test to highlight the importance of secure electrical connections? The fuse holders that came out of the Supra use simple spade terminals. These terminals rely on the spring tension of the sides of the body to hold the fuse in place. As such, they are similar to the spade connectors used to connect to spade terminals on a speaker or the terminals of a relay. So let’s wire up some 10-AWG wire to an amplifier, install a 30-amp fuse inline and then make some measurements.

With the terminals tightly secured to the fuse, there’s a voltage drop of 188.6 millivolts across the wires and connectors with 30 amps of current flowing through our test connection. That works out to resistance of 3.953 milliohms and dissipation of 3.558 watts of heat energy. The thermal image below was taken after 60 seconds at a current flow of 30 amps through the connection.

What happens if we take the fuse out of the terminals a few dozen times to loosen the connection? I did that and repeated the test. I measured 121 millivolts across the wires, which means our resistance has increased slightly to 4.03 milliohms, and it was wasting 3.63 watts of energy to heat. Thankfully, that’s not much of a change.

To exaggerate our example, what if we open up the connection with a screwdriver to show a worst-case scenario? The fuse stays in place but definitely doesn’t require much pressure to install it. Now there are 223 millivolts across the fuse, terminals and wires. At a draw of 30 amps of current, that’s 7.433 milliohms of resistance and 6.69 watts of heat. While it doesn’t sound like much, a fuse doesn’t have much surface area, so heat energy is concentrated in a small space. The thermal image below was taken after 60 seconds of 30 amps of current flowing through the poor connection.

If a technician is attempting to troubleshoot a loose or intermittent connection, a digital multimeter isn’t going to recognize the difference between four and seven milliohms of resistance. Having a thermal imaging camera can be very helpful.

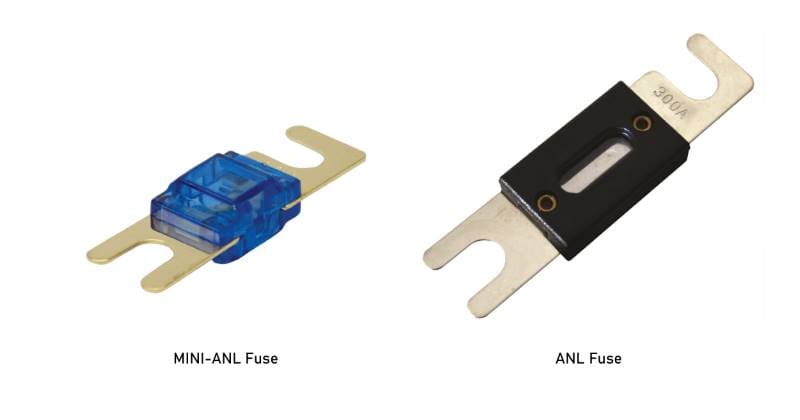

I’m Not Fond of Blade Fuses

Frankly, I’m not a fan of ATC/ATO, MAXI or AGU cylindrical glass fuses. These protection devices rely on some spring connections to minimize resistance and ensure current flow. If you want to maximize the reliability of your car audio or an accessory upgrade, then ask your retailer to use a Mini-ANL or ANL fuse holder. The technician can tighten the fuse in place in place with a threaded fastener.

Ensure that Your Audio System Is Protected Properly

When you have an audio system or another high-current upgrade (winch, lighting, etc.) installed in your car or truck, ensure that the technician executes high-quality connections made with the correct crimper for the application. Every connection should be both mechanically secure and be optimized for maximum electrical conductivity. Where possible, choose ANL or MINI-ANL fuse holders. Your local specialty mobile enhancement retailer should have options available to choose from.