Home and car audio speakers are surprisingly simple devices in concept, but their quality and performance hold complex considerations. If you’ve been a longtime reader of our articles here at BestCarAudio.com, you know we strive to educate consumers about how car audio upgrades like speakers work and what separates one from another. In this article, we will once again dive into the murky waters surrounding the discussion of the speaker break-in process and clarify things with an analogy.

Loudspeaker Thiele/Small Parameters

Engineers needed a set of parameters describing a speaker’s characteristics to calculate the low-frequency performance of a moving-coil loudspeaker and its interaction with an enclosure. Predicting the output of a speaker in an acoustic suspension (sealed) or bass reflex (vented) enclosure is easy if the Thiele/Small parameters are available. For this discussion, we’ll consider two parameters: the driver’s resonant frequency (Fs) and its equivalent compliance (Vas).

The resonant frequency of a speaker is the frequency at which the mass of the moving assembly (cone, part of the surround, the former, the voice coil and part of the spider) resonates naturally. Think of this like the sound you hear when you blow air over a glass bottle that’s partially filled with soda or water. At the resonant frequency of this system, a small input of air results in a relatively significant amount of sound production. The same applies to a speaker. At the resonant frequency, a small signal from an amplifier results in a relatively large amount of cone motion.

The equivalent compliance of a speaker is slightly more complex. The spider and surround components are springs designed to bring the cone assembly back to rest when the audio signal stops. To quantify the stiffness of the springs, we refer to a volume of air that when occupying 1 cubic meter of space exerts the same force as the speaker’s suspension. A low Vas value for a 10-inch subwoofer, like 9 liters, would represent a relatively stiff suspension. A value of 29 liters is on the softer end of the compliance range. For the purposes of this explanation, the word compliance can be considered the inverse of stiffness.

Speaker Suspension Components

Regarding its effect on the speaker cone’s compliance, the spider at the base of the cone presents the majority of the resistance to motion. Spiders are typically made from woven textiles like polyester, cotton, Nomex, Kapton, aramids or glass fibers impregnated with a phenolic resin. The choice of spider materials, the number of threads and the thickness of each thread, the amount of resin and, of course, the shape of the spider all combine to determine its stiffness. Thicker means stiffer in this discussion.

Consider an analogue of a spider for a moment. If you took a cotton T-shirt and painted it with glue, it would likely stay flat once dried, even if held in the air by one corner. However, if you crumpled the shirt into a ball and broke some of the glue’s bond, the material would sag or droop around where you were holding it. Some spiders behave similarly.

When a spider is new, the bond between the phenolic resin and the fibers is as strong and rigid as it ever will be. However, as the spider stretches upward and downward with the speaker cone movement, some of those bonds weaken, allowing the spider to move more easily. This is what changes as a speaker “breaks in.” The spider becomes less stiff (more compliant), and the Vas increases, decreasing the Fs frequency. In short, it becomes easier for the voice coil to move the speaker cone.

Here’s the first caveat: Not all speakers use spiders with a significant amount of resin. Some change in compliance by a very small amount, even after hundreds of hours of playtime. Others change significantly, which not only changes the Vas and Fs of the driver but the frequency response and damping characteristics of the assembly. The only way for a car audio technician or a consumer to know if a speaker needs to be “broken in” is to break it in and see if it changes. I measure the Thiele/Small parameters of all the speakers and subwoofers I review before and after the break-in process to quantify any changes that might take place.

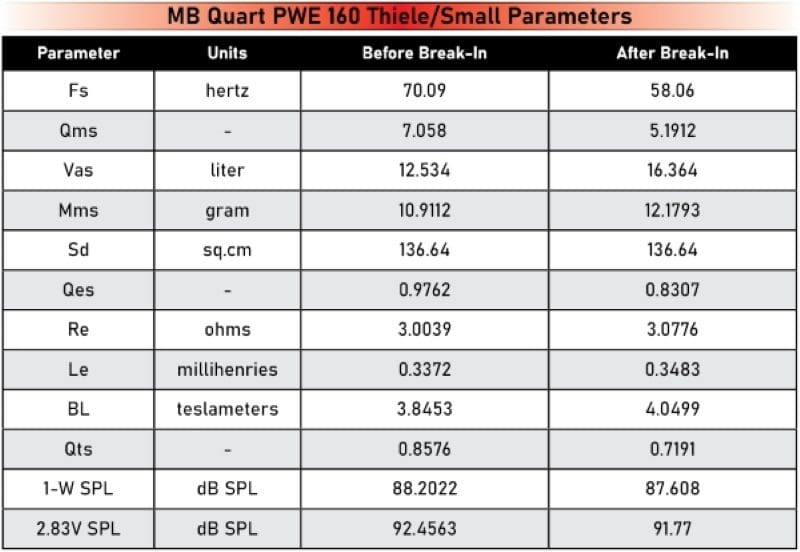

If we look at the specifications for this old MB Quart speaker, we can see that many of the Thiele/Small parameters changed after only eight hours of break-in on the bench. For example, the resonant frequency dropped from 70 to 58 Hz, and the equivalent compliance increased from 12.53 to 16.36 cubic feet. However, what matters most to the speaker’s sound quality is the resulting drop of the Qts value from 0.8576 to 0.7191. This change would dramatically reduce emphasis in the lower midrange and make the driver sound much tighter and more controlled.

The Speaker Break-In Analogy

Hopefully, you’re still with us. We admit the above can be somewhat complicated. Nevertheless, we recently had a bit of an epiphany that might help you understand the speaker break-in process. Consider a pair of fine Italian leather dress shoes like those from Cole Haan or Allen Edmonds. New leather dress shoes can be somewhat stiff and uncomfortable. For the first four or five times you wear these shoes to an event, they may be uncomfortable, even if they are the perfect size for you. The leather needs time to flex and conform to the specific curves and contours of your feet. This is a process that takes time. If you don’t wear them, they don’t change their shape, and they won’t become enjoyable to wear.

Image Credit: Potter and Sons / Trenton and Heath YouTube

Are you seeing the similarity to a speaker in our analogy of the dress shoes? Both need to be “exercised” to get into a state where they are something that you will enjoy using. Some shoes conform quickly, just as some speakers change very little. Other shoes can take weeks or a month to get comfortable, the same way some speakers need extensive use to soften the suspension components. The only way to know whether your shoes will take time to be comfortable is to start wearing them.

A second important similarity between shoes and speakers is that how you break them in, or whether or not you break them in, does not affect their long-term performance. In this capacity, the process differs from breaking in the camshaft and lifters or piston rings in a car or truck engine. If an engine isn’t broken in properly, it may not operate at its peak performance level or experience unwanted wear early in its life.

On the contrary, speakers and shoes will last the same length of time whether you baby them or put them to work immediately. I’ve seen many freshly built competition-level subwoofers subjected to thousands of watts of power on their first round of competition. On the shoe side, the only detrimental factor to an extended initial period of wearing them would be that your feet may be sore. A few dinner meetings would be better for your feet than a day of standing at a trade show. Ultimately, the shoes don’t care how much you wear them.

To Break In or Not – That is the Question

If you want to ensure that the subwoofers or speakers being installed in your vehicle will sound the best they can from day one, ask the shop that’s installing them to break them in overnight before you arrive for your appointment. The process is easy and safe. The worst-case scenario is that the speaker’s specifications and performance don’t change much. Conversely, some need to be exercised to sound good. This break-in process can reduce the need to return for further fine-tuning of a digital signal processor or another equalizer.

Image Credit: Special thanks to Dan Bishop at Scrivener’s Men’s Apparel at 389 Brant St. in Burlington, Ontario, for letting our team photograph several of their shoes for this article.