One thing common to every car audio subwoofer enclosure is that they need to connect to the subwoofer amplifier. Most subwoofer enclosures include a terminal cup or something similar to facilitate easy connection to the subwoofers. Let’s look at subwoofer enclosure speaker wire connection options.

Guess What? Ohm’s Law

If you’re serious about car audio, Ohm’s law should be tattooed on your body – or at least, you should understand it explicitly. Almost every electrical connection requires some consideration of voltage, current and resistance. Regarding subwoofer enclosure terminals, we’ve seen many discussions where the primary consideration was power. In reality, power isn’t the issue – current is.

Let’s say you have an 800-watt amplifier powering your subwoofer enclosure. If the subwoofers in the enclosure have a net nominal impedance of 4 ohms, the amplifier must flow 14.14 amps through the wires to the enclosure. In terms of appropriately sized wiring, if your installation uses 5 feet of 16 AWG wire, you’d waste 1% of the energy from the amp as losses in the wire itself. Eight watts isn’t much and isn’t anything to worry about. Jump to 12 AWG, and the losses are only 3.4 watts. It’s still not something you’re going to lose sleep over.

These days, most car audio amplifier manufacturers offer subwoofer amplifiers designed to produce power into lower impedance loads. Let’s say your amplifier delivers 800 watts into a 2-ohm load. The amp must provide 20 amps of current to make the same power. Losses in the wiring still aren’t a huge issue. Five feet of all-copper, full-sized 16 AWG wire would convert 17 of the 800 watts into heat. Jumping to 12 AWG drops that to 6.8 watts. Still not a mess.

Let’s say your subwoofer enclosure has a nominal impedance of 1 ohm, and your chosen amp can deliver 800 watts into this impedance. We are now talking about 28 amps of current flowing through the speaker wire. That 5-foot run of 16 AWG wire would waste 34.4 watts of energy. The issue is that the power is wasted as heat. Dissipating almost 35 watts of heat is challenging, and the wire will get warm. When conductors increase in temperature, their resistance increases. That’s a whole other can of worms! If your installer uses 12 AWG wire to connect your amp to your subwoofers, the losses are down around 13.6 watts – which is pretty safe.

A quick side note about low-impedance subwoofer loads: All but two or three of the hundreds of amplifiers I’ve tested increase the distortion they add to an audio signal when driving lower impedance loads. Every amplifier I’ve tested presents a significant reduction in amplifier efficiency caused by running subwoofers at lower impedances. If you care about sound quality in any way, you’ll find a nice two-channel amp and bridge it to run your subwoofers at a 4-ohm load.

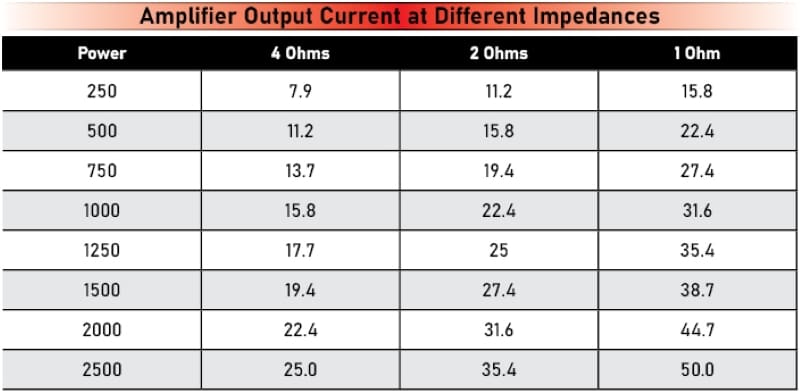

Here’s a quick chart to show how much current is required to feed subwoofers with different power levels of amplifiers and 4-, 2-and 1-ohm loads.

Any time current flows through a connection, there is going to be some amount of resistance. When current flows through a resistor, be it resistance in a connection or an actual resistor component, heat is generated. The formula to calculate the power wasted in a resistor is P = R x I x I. As the current in the equation is squared (I x I), small increases in current flow result in significant increases in the amount of wasted power and heat created.

Subwoofer Enclosure Terminal Cups and Connections

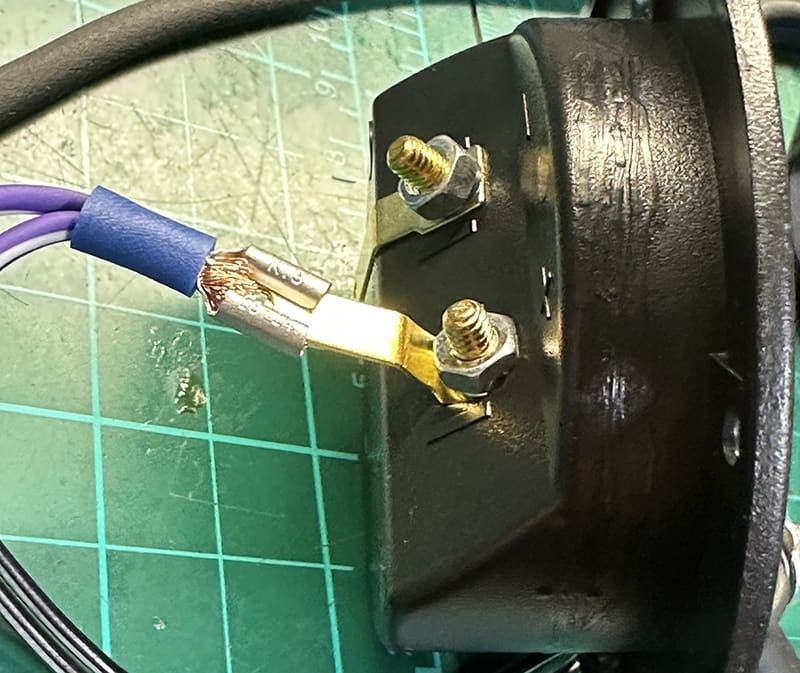

If you visit a local specialty mobile enhancement retailer and look at the prefabricated subwoofer enclosures they offer, you’ll see a variety of terminal cup solutions. Some use large binding posts that accept bare wire up to 10 or even 8 AWG. Others use small spring-loaded terminals that might accept 14 AWG wire.

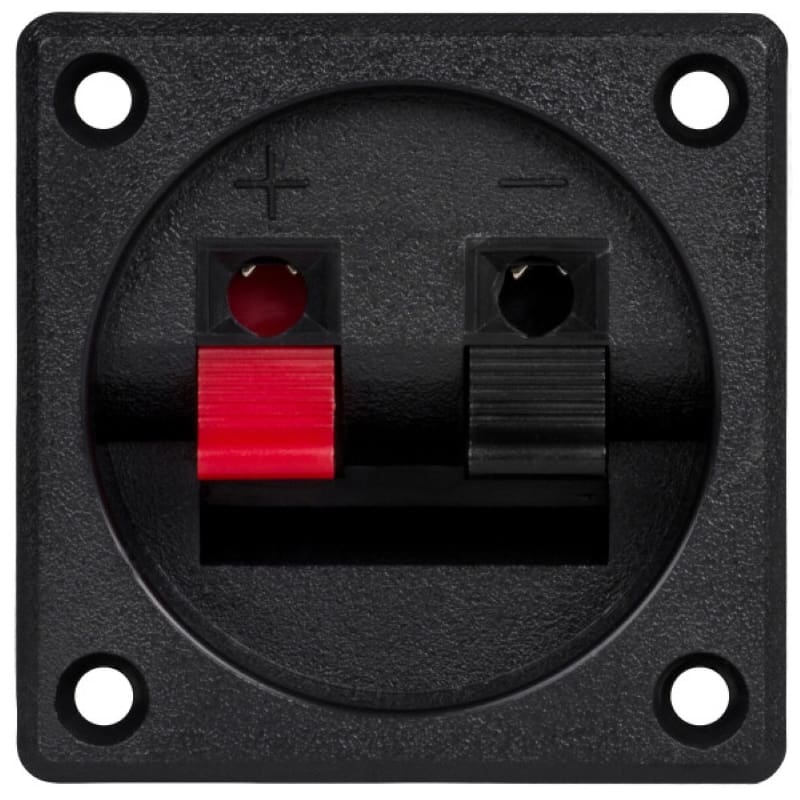

The first terminal we’ll look at is the basic spring-loaded terminal type. This terminal type will be the least ideal for conducting surface area between the speaker wire from your amplifier and the connections inside the amplifier. All the current has to pass through a thin piece of stamped steel. We see people sharing images of these terminals melting all the time.

The next step up in terminal cup quality is also spring-loaded but has significantly more surface area. These terminals pass the current through a stud rather than a piece of stamped steel.

A common drawback with this type of connection is that some are designed so the clamping portion doesn’t squeeze small-gauge wire well. If the speaker wire is flopping around loose, things will get hot when you pour on the power. If the springs have enough pressure, the right size wire is used and the wire is inserted properly, these should work better than the previous option.

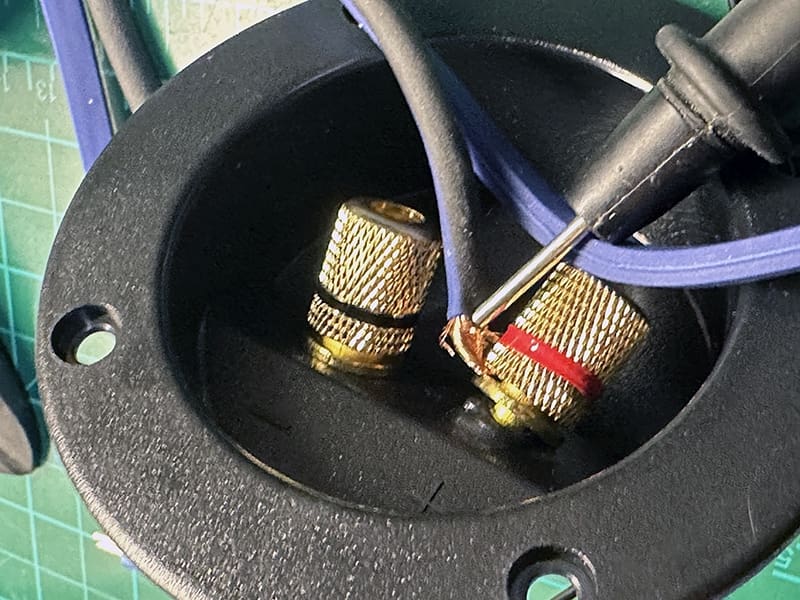

The last terminal cups we’ll look at are called binding posts. These are similar to the previous cup in that the wire is inserted into a hole in the center stud. A nut threads down to secure the connection rather than a spring applying pressure to the wire.

The number one issue is whether or not the nuts are tightened correctly and if they stay tight. If anything were to loosen over time, you’d end up with a high-resistance connection, which will produce significant amounts of heat.

If your car audio system uses binding posts, it’s worth checking them frequently to make sure they’re tight.

Testing Subwoofer Terminal Cups

So, just how much current can a terminal cup handle? As you can imagine, this is an excellent idea for some testing. We rounded up a few cups and connected them to the power wire on an amplifier. With a shunt resistor in series, we can accurately measure current flow. We wired the terminal cups up one at a time and slowly increased the current flow until they produced significant amounts of heat. We’ll give them an approximate current rating based on being able to handle two minutes at a specific current level. You can use the chart above to determine the amount of power the cup can handle based on the impedance of your subwoofers.

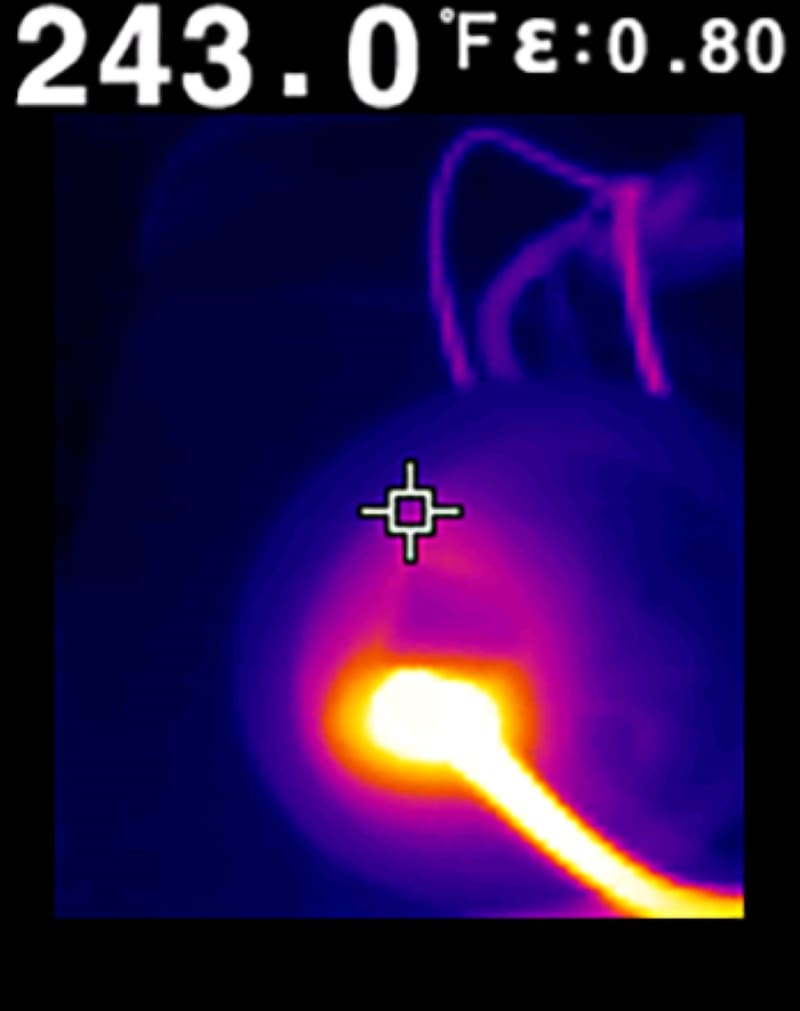

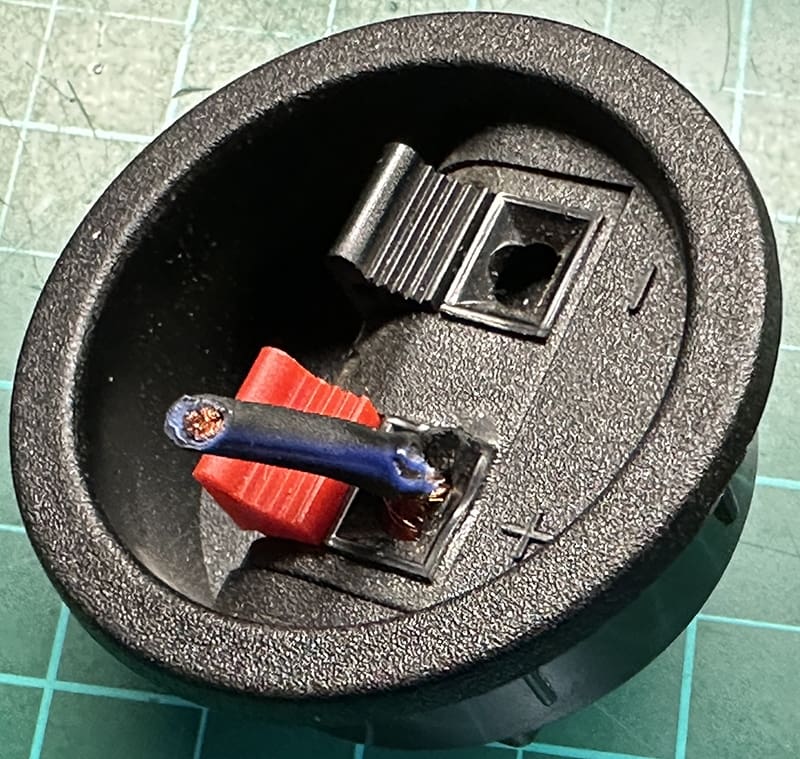

Up first was the inexpensive spring-loaded cup. We started with 5 amps of current. Not much exciting happened, and the connection generated no heat. Things stayed pretty steady as we increased current. The voltage drop also increased reasonably steadily. By 15 amps of current, the connection to the wire was producing 100 degrees F of heat. Fifteen amps equals 225 watts with the subwoofers wired to a 1-ohm load. Things started to go south at 23 amps of current, or just over 500 watts when wired to 1-ohm. The connection increased in temperature faster. At 24 amps, I could smell something, and the connection was over 180 degrees. At 25 amps, the plastic spring block started to smoke, and the connector melted. The wire is now permanently attached to the cup.

The other terminal cup I had here in the lab was a threaded binding-post style. I hypothesized that the added surface area of the center post, combined with the nut on the back securing the tab in place, would help provide less resistance and, thus, more current carrying capacity.

Once again, things seemed fine with current levels up to about 6 amps, with no measurable heat at the connection. Six amps equals 36 watts of power to a 1-ohm load. As with the inexpensive spring-loaded block, resistance increased as the current flow increased. The connection reached 100.5 degrees with 18 amps of current, which is only slightly better than the first terminal. However, this is nowhere near the performance I expected. At 28 amps of current, or 784 watts into a 1-ohm load, the entire metal assembly had melted the plastic, and the terminal started drooping.

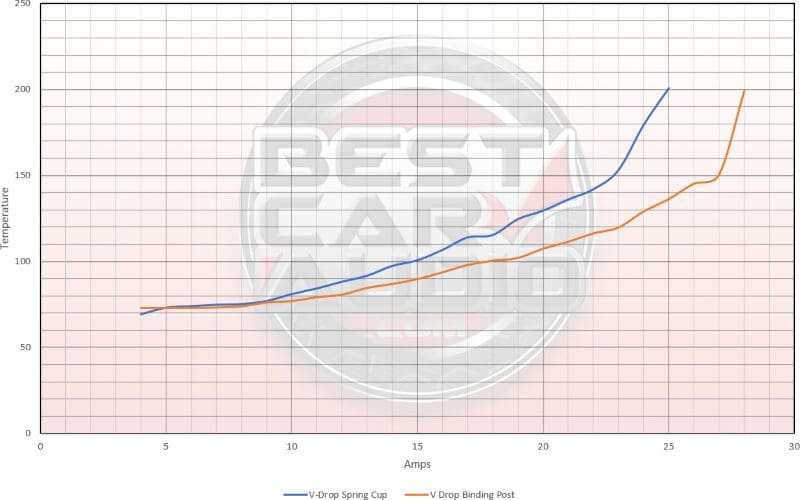

Let’s do some quick math on my measurements during the testing. First, I measured the voltage drop from the wire connected to the terminal (just beside the connector) to the terminal strip on the back of each terminal cup. The graph below shows the blue spring-loaded cup and the orange binding post.

I used my thermal imaging camera to measure the temperature of each connection at each current level.

If we want to extrapolate some current handling limits from the day, the spring-loaded cup is good for about 22 amps of current, and the binding post cup can handle about 25 amps. These are, of course, continuous current numbers. These correlate to 484 watts at 1 ohm, 968 watts at 2 ohms and 1,936 watts at 4 ohms for the spring-loaded cup. The binding post can theoretically handle 625 watts at 1 ohm, 1,250 at 2 ohms, and 2,500 at 4 ohms.

There are a few caveats to this test. These are continuous current measurements. If you’re listening to very dynamic music, you can likely use more power. However, things don’t take long to melt at the upper limits, so be cautious in choosing your subwoofer enclosure.

Another caveat is that we used 14 AWG all-copper wire. You may experience different performance levels with larger or smaller conductors.

The Best Way to Connect to a Subwoofer Enclosure

Doing this quick test also gave us the idea to test a few quick-connect styles as suitable solutions for delivering significant amounts of power to a subwoofer enclosure. You’ll have to watch for that article soon. In the meantime, we suggest choosing an enclosure that uses multiple terminals if you’re attempting to deliver significant power at low impedances. Your local specialty mobile enhancement retailer can then run multiple speaker wires back to the amplifier to improve efficiency and provide an audio system that is as reliable as possible. Better yet, forego any connector and ask them to run the speaker wires directly from the amp to the subwoofers and seal the wire where it enters the enclosure.