A short while back, we looked at the stunning Audi Q3 demo vehicle built by Pinnacle Autosound in Lake City, Florida. We were so impressed with the attention to detail in the project that we decided to do two “behind the scenes” articles on how the project came together. This article examined the processes and techniques used to install the Morel speakers. Now it’s time to check out the amazing amp rack and subwoofer enclosure design and fabrication process.

Amp Rack Design Concept

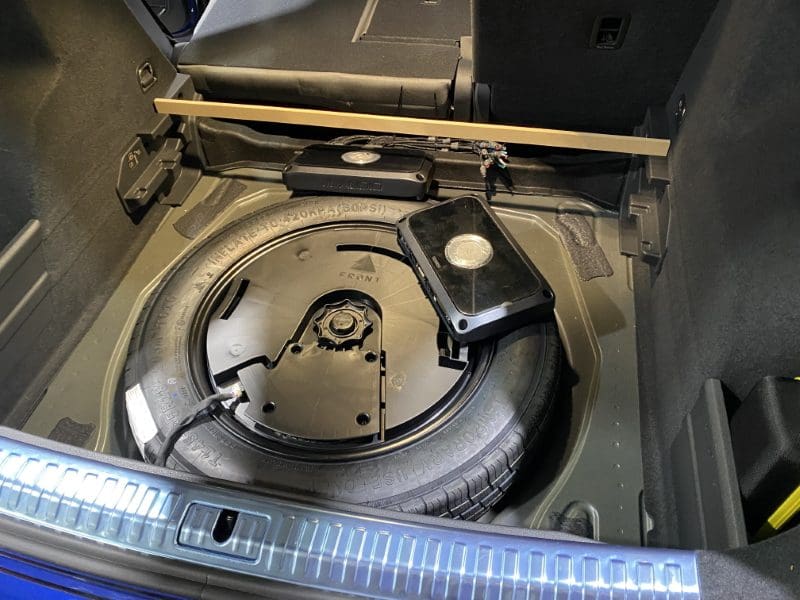

JOey Knapp, the owner of Pinnacle Autosound, wanted to maintain the cargo-carrying capabilities of his Audi Q3. Of course, he didn’t want to give up the amazing stereo system he’d designed and installed. The amp rack design would keep the three JL Audio VXi amplifiers in the vehicle and feature a removable subwoofer should he want to bring the spare tire with him on a long trip.

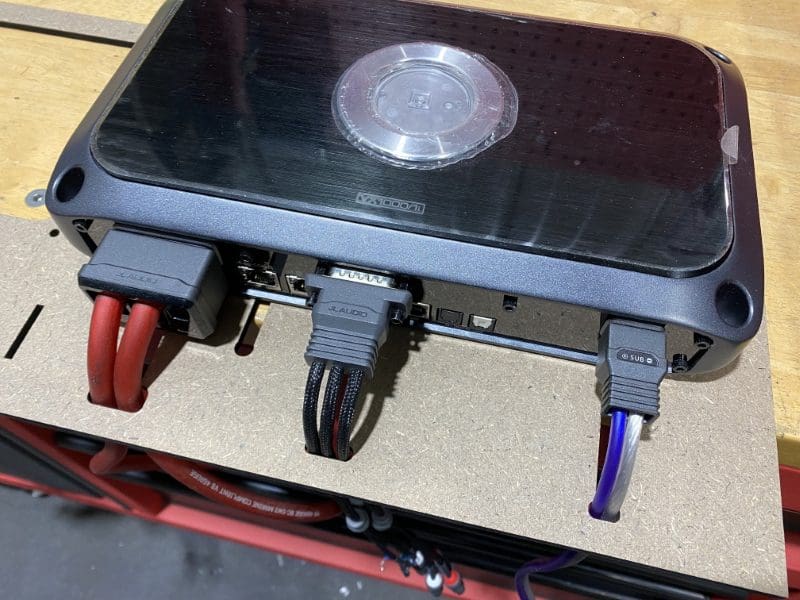

JOey started the design by taking measurements of the amplifiers he intended to use and the available space in the cargo area. Once he knew the three amplifiers would fit side by side, he started designing a solution to manage all the wiring to and from the amps so the installation would remain tidy.

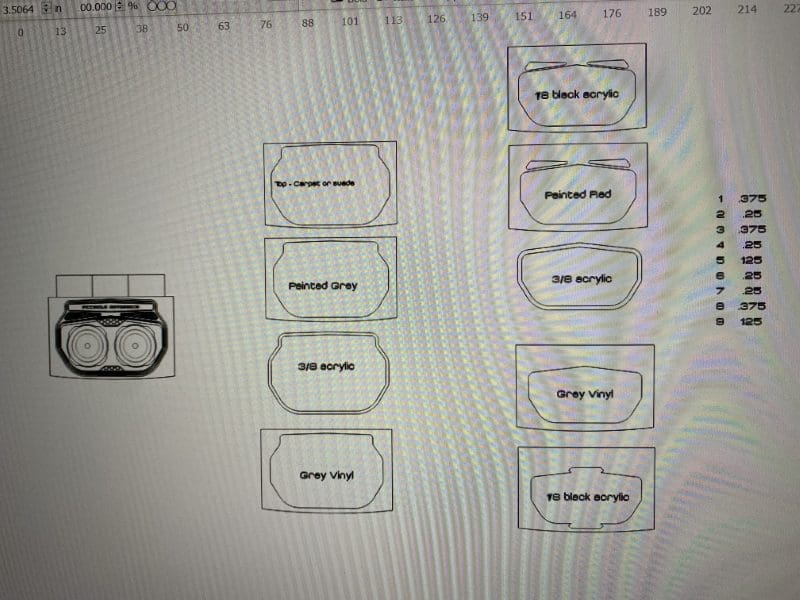

JOey is impressively adept at vector-based artwork and design in Adobe Illustrator and LightBurn. As of the start of the project, he hadn’t ventured into 3D design. Wanting to expand his skill set and client options, he taught himself the basics of Fusion 360 and designed the amp rack using that software package. After he had an initial concept, he used his CNC laser to cut a cardboard test piece. After a minor adjustment, he scaled up the prototype process and cut the entire amp rack out of thin wood pieces to ensure that everything fit into the vehicle perfectly.

The final drawings fed his CNC plasma table to cut 14-gauge cold-rolled steel. The amp rack design includes mounting positions for the amplifiers on the top layer and a second layer with a spot for the Vxi-HUB, power distribution blocks and terminal strips for all the speaker connections. JOey also used wire management tabs and pathways to ensure that nothing would rattle or buzz as the vehicle was in motion. Each plate has tabs and slots, so everything pieces together like a three-dimensional jigsaw puzzle. JOey ensured everything was perfectly square on his welding table before fusing the elements together. After a final test fit, he sanded and primed the amp rack and painted it black.

The amp rack is secured to the vehicle using six nutserts inserted into the high-strength steel cross member at the rear of the cargo area.

Audi Q3 Subwoofer Enclosure

JOey knew that he wanted the audio system in the Audi to be capable of impressive bass levels. As such, choosing two JL Audio 13.5-inch subwoofers made perfect sense. As mentioned, JOey wanted to be able to remove the enclosure and put the spare tire back in for long trips.

As you may know, JOey worked with “False Floor King” Bing Xu at Simplicity in Sound (SiS), in Milpitas, California. As his honorary but highly appropriate title implies, Bing has built a LOT of audio systems with false floors in the cargo area. JOey took some inspiration from those experiences and decided that the Q3 would follow Bing’s design style. While many false floor designs are chosen for cosmetics, JOey designed this so that he could use the spare tire cover that came with the Q3. He can load groceries or shop supplies in the vehicle without damaging the subwoofers. In short, as JOey put it, “The cargo area is designed in true SiS fashion.” We love designers that give credit to those who’ve inspired them!

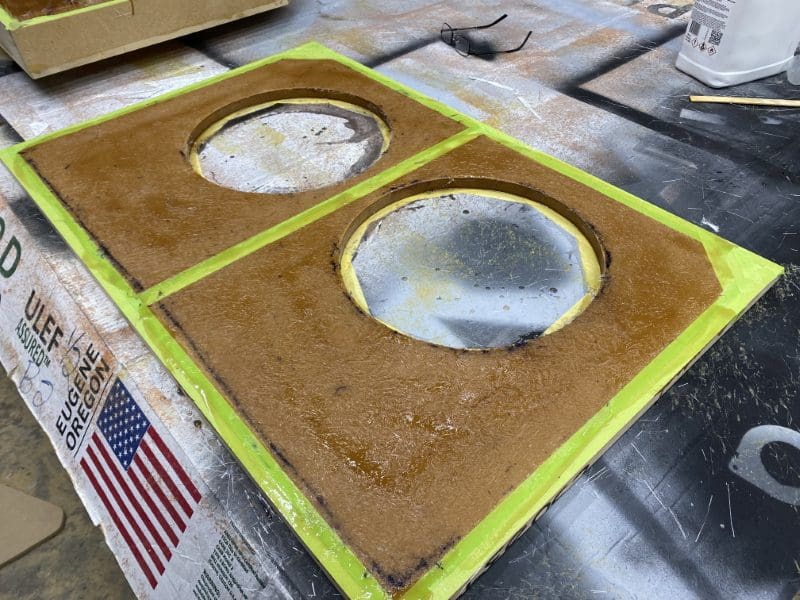

The subwoofer enclosure started with an MDF panel cut to fit into the bottom of the spare tire well. From there, three rings build up the enclosure’s height around the well’s perimeter. Another panel with an opening that matches the inside of the rings extends the enclosure to the edges of the trunk. A divider and sides increase the enclosure depth.

Knowing that MDF is surprisingly porous, JOey painted the underside of the top panel and the inside of the enclosure with fiberglass resin. He added several layers of chopped fiberglass mat to ensure that the resin couldn’t crack if stressed. You’ll note that everywhere that the two panels will mate was protected with green masking tape. Once the resin had cured, he cut the edges along the tape edge to reveal a clean mounting surface to ensure a perfect seal between the two parts.

Audi Q3 Cargo Area Trim Panel

JOey knew the shop’s demo vehicle was his best opportunity to show off his design and fabrication skills. JOey also happens to be an amazing graphic designer. He drew a multilayered trim panel in LightBurn software, based on the amplifier and subwoofer mounting locations. The trim piece has six acrylic layers and three painted MDF layers to add additional style.

The enclosure’s top panel features light-gray vinyl to serve as a base for the cosmetics. Vinyl works as a gasket so that the subwoofers seal perfectly. From there, layers of black, white, clear and vinyl-wrapped acrylic build up to the top piece. JOey painted several pieces in the same metallic blue as the vehicle and cut hexagons into the design with the CNC laser. He added the Pinnacle Autosound logo and etched hexagons on either side of that. The transparent layers of acrylic are backlit with addressable LED lighting to make the trunk pop at night. The lighting is wired with three separate zones and has three controllers. He can have everything match or set it to contrasting colors to highlight a specific portion. Aside from how great it looks, we are always amazed at how master fabricators like JOey can envision how each component will nest with the adjacent pieces to create a stunning final product.

One interesting design note that JOey shared with us is in relation to hex-based trim pieces just in front of and behind the subwoofers, as well as the eyebrow-shaped inserts. He had considered forgoing the complex shapes for a cleaner, more streamlined look. Rather than go back and forth or suffer from what he called “analysis paralysis,” he made those parts removable. If he didn’t like the way they looked, he could cut different replacements in a very short amount of time. He can also change them to a different color or eliminate them altogether.

Columbia County’s Car Audio Upgrade Experts

And there you have it. This Audi Q3 is a perfect example of how a modern car audio shop can integrate a stunning sound system into a late-model vehicle. Using these integration techniques, a vehicle can be returned to its original condition in hours if the owner wants to sell it without the system or return it at the end of a lease.

As we have often said, shopping for the right shop to upgrade your vehicle isn’t easy. There aren’t a lot of shops like Pinnacle Autosound out there. Now you have an idea of what to expect when getting quotes on upgrades for your car or truck. Of course, if you live in Florida or Georgia, it’s easiest to take a run to Lake City and talk to Brian and JOey. Be sure to tell them the guys from BestCarAudio.com sent you!