If you’re into high-end car audio or auto sound competition, you’re likely familiar with Fred Lynch and the company ARC Audio. Fred has worked for ARC Audio for over 18 years and has built several unique audio systems in his cars to show off their products. His latest vehicle purchase was the 2019 Ford Flex you see here. Fred had no significant plans to upgrade the Flex, even to the point that when asked about his plans, he repeatedly joked, “Stock rocks.” But as happens with those of us in the industry, things quickly spiral out of control.

Keep It Stock!?

When Fred told his better half, Mindy, about his plan to purchase the Flex, she made him promise that he wouldn’t turn it into another show vehicle. All we can say is that Fred tried. He told us that about a week after taking delivery of the Flex, he was in Los Angeles working on one of the builds for Overhaulin’. During a break, Chip Foose and Fred talked about the Flex, and Chip asked to see the vehicle. A few minutes into the conversation, Chip uttered some of the most dangerous words known to a car guy: “You know what would look good?” Fred’s six-hour drive home to Modesto at the end of the week gave him more time to ponder changes, upgrades and audio system designs for the Flex.

Back home, Fred told Mindy about the discussion and the ensuing drawings and ideas. Mindy had prepared for this moment, as she’d already crafted a list of restrictions for the project. Fred smiled intently as she ran down the rules:

The stereo system can’t take up any storage space and must leave room for the stroller, groceries and luggage for road trips. The audio system had to be easy to use, so things like multiple volume controls weren’t an option. The interior had to look as though it had rolled off the showroom floor. Any added audio equipment needed to be concealed as much as possible. The vehicle couldn’t be cut up or modified in a way that would reduce its resale value. They still needed to be able to fold down the rear seats. And finally, they had to be able to return the vehicle to its original condition without spending thousands of dollars on replacement interior panels.

Like any good car audio guy, Fred saw these requirements as challenges rather than limitations.

Establishing a Plan and a Foundation

After talking with his co-workers and industry peers, Fred put together a plan to create an audio system that would not only sound amazing and play loudly but would integrate perfectly with the factory electronics in the Flex. A number of convenience systems would also be added to the vehicle to make it more enjoyable.

The first step was to remove the interior to install sound deadening. Fred contacted the folks at Dynamat to order Dynaliner, Dyamat Xtreme and Hoodliner for the vehicle. With the help of his son Fred Jr., the gentlemen completely stripped the interior to make way for hundreds of square feet of noise control products. Each panel was treated with an edge-to-edge layer of Dynamat Xtreme, then covered with Dynaliner to improve thermal isolation and high-frequency noise absorption. A single layer of automotive-grade jute was added for extended thermal and comfort properties. Finally, Fred added panels of Dynaliner Max that he had left over from a previous project to the driver and passenger footwells to absorb more sound energy.

With the foundation established, Fred reached out to Stinger to procure power wire, interconnect cables, speaker wire, power distribution blocks, fuse blocks and circuit breakers for the project. The pair of Freds ran 0-AWG power cable from a Stinger circuit breaker under the hood to the passenger-side rear of the vehicle. They also ran new wiring to the factory electrical system’s power distribution points and upgraded all the vehicle grounds, including an upgraded ground from the battery to the rear of the vehicle. All of the new wiring is protected with a braided nylon loom to reduce the chance of damage. The stock battery was upgraded with a Stinger Power2 Series AGM battery.

To Protect and Serve

Since Fred frequently travels between Modesto and Los Angeles working on projects for ARC Audio, he wanted some assistance preventing conversations with local law enforcement officers. So he turned to K40 and invested in one of its K40 360 Platinum integrated radar detection and laser defense systems with auto filter sensitivity technology. With the vehicle apart, Fred and his son went through the painstaking process of integrating all the wiring for the front and rear radar receivers, along with three forward-facing Laser Defusers, into the factory wire harnesses. Where possible, he added pins to existing electrical OEM connections or added secondary OEM-style weathertight plugs to ensure that the vehicle would remain easily serviceable.

Out front, the Laser Defusers are concealed by custom-molded IR Transparent acrylic plastic panels that appear black but remain invisible to laser signals. The warning LEDs are mounted inside the car’s instrument cluster and integrated into the cluster cosmetics utilizing part of the OEM acrylic accents within the cluster, making them easy to see yet wholly hidden when not illuminated.

Fred turned to Firstech for one of its Compustar remote car starter and security systems to protect the Flex and add some convenience. The system is based around a CM7200-series controller and the T12 two-way remote control that offers up to 3 miles of range. Fred also installed a DroneMobile telematics system to monitor the vehicle even if he’s on the other side of the world for a business trip. In addition, he added the Firstech “Alarm It” kit with a siren and a programmable digital shock and tilt sensor for additional visual and audible deterrence.

Lastly, Fred installed a Momento M6 dashcam system in the Flex. The forward-facing camera includes a Wi-Fi hotspot that makes it easy to download video to a smartphone. The system also includes a second camera that Fred mounted on the rear glass after routing the wiring through the wire harness boot between the body and the hatch. The system records video from both cameras to a micro-SD memory card anytime the ignition is on in the vehicle.

Integrated Audio System

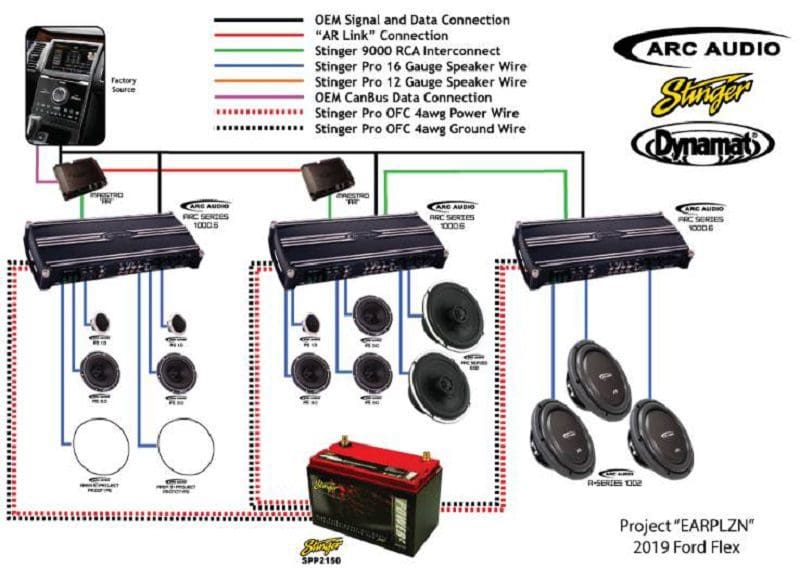

In keeping with the plan to integrate the sound system seamlessly into the Flex, Fred reached out to his contacts at iDatalink to ask about system expansion opportunities with their Maestro AR amplifier replacement modules. After some back and forth with both the iDatalink and the ARC Audio engineering teams, a proper “world’s first” solution was created. Because the PS8Pro digital signal processors are addressable, iDatalink created custom software that would allow more than one AR module to be installed simultaneously in the Flex. The initial “AR” module would receive the commands from the vehicle’s OEM communications bus, then forward relevant commands to additional AR modules in the system. The result is the ability to deliver completely programmable OEM control and interface solutions beyond the typical six or eight channels found in most integration module-based systems. In this case, this solution opened up the opportunity for a nearly unlimited number of channels for the system.

To ensure that the signal going to the AR modules from the factory radio was as clean as possible, Fred removed the wiring from the source unit connector and extracted it from the factory harness. Next, the OEM wiring for each pair of input channels was twisted together individually before being bundled back in place and loomed for consistency of the install and OEM presentation and secured at 4-inch intervals. He made the connection to the factory harness using the Maestro F02 Adapter in conjunction with a pair of ARC Audio IDATA-OEM signal harness adapters.

With the source taken care of, the next step was to find a home for the system’s amplifiers. Fred removed the factory-installed subwoofer enclosure and amplifier from the passenger-side rear quarter panel area and, with some weekend help from co-worker Brian Mitchell, created aluminum brackets that would hold three ARC 1000.6 amplifiers in that space under the factory interior panel. In terms of power, the ARC 1000.6 amps are “rated” to produce 175 watts per channel and can be bridged to deliver 350 watts per pair of channels into 4-ohm loads. If you’ve seen our review of the ARC 1000.4 DSP, you’ll know these monsters are seriously under-rated.

Two of the ARC Audio 1000.6 amplifiers had ARC Audio IPS8.8 Digital Signal Processors installed, giving the system 16 channels of active processing. Having the processors in the amplifiers also helped to keep the wiring neat and tidy. The third 1000.6 amplifier runs passively with signal outputs from the processors on the first two amplifiers.

Three Stinger XLINK fuse blocks are installed near the seat belt mechanism in the C-pillar area. The panel can be removed without tools, and an appropriately sized Snap-On Allen wrench is mounted by the fuses for easy removal and replacement.

The grille from the factory subwoofer now serves as a cooling exhaust vent for the amplifiers. Fred searched for the quietest fan he could find that would still move a significant amount of air. A flap system in front of an additional exhaust fan mounted to one of the vehicle’s environmental exhaust vents prevents exterior air from feeding back into the vehicle and also allows for airflow even when the fan isn’t in operation. Additionally, Fred tapped into the Flex’s rear secondary climate control system to route cooled air to the amps in the summer. For winter months, the added additional vent can be closed to prevent filling the amp rack area with heated air from the vehicle’s secondary heating system.

Speakers and Subwoofers Are the Final Link

The last step in upgrading the sound system in the Flex was to integrate 12 new speakers and three subwoofers. Fred commissioned Brian Mitchell to laser cut custom acrylic mounting plates and spacers for the door speakers. Next, Fred bonded the rings together to mount a set of custom-built 8-inch woofers in the stock locations in the front door and a set of ARC 602 coaxial speakers in the rear doors.

Because this was intended as a completely integrated upgrade, Fred depinned and removed the factory 20-gauge speaker wires in the factory harness (where feasible) and upgraded them with 16-AWG OFC Stinger speaker wire to feed each speaker. With the doors reassembled, Fred then turned his attention to the dash to create an acrylic mount for a single ARC Audio RS 1.0 tweeter and RS 3.0 3-inch midrange driver in the center speaker location. He also installed a set of RS 3.0 midrange drivers in the factory locations in the D-pillars at the very rear of the vehicle.

The last step was to create a set of low-profile unobtrusive A-pillar pods for the RS 1.0 tweeters and RS 3.0 midrange drivers. The sealed pods were constructed using fiberglass over an acrylic mounting plate. This was the one area that Mindy gave some space on the “OEM look” requirement since Fred did not want a stepped speaker pod with grilles that would interfere with the speakers’ performance. When they were finished and sanded smooth, Fred wrapped the new trim pieces with a cloth that matches the factory-installed upholstery.

Bring the Bass!

The subwoofer system in the Flex is based around three of ARC Audio’s new A-Series shallow-mount subwoofers. Fred and his son created a fiberglass enclosure with an integrated tub that sits into the spare tire well in the vehicle’s cargo area. The spare tire was removed with Mindy’s approval and replaced with a can of Fix-a-Flat and a subscription to roadside care.

Three of the A10D2 10-inch, dual 2-ohm voice coil subwoofers are mounted face-down in the common chamber tub. Each subwoofer is powered by a pair of channels from the third ARC 1000.6 amplifier. The subwoofer system can be concealed under the rear cargo area trim panel when desired, still allowing the rear seats to be folded completely flat to take advantage of the vehicle’s expanded cargo area features. Fred asked us to thank to Rex Williams for the paint work on the subwoofer tub.

It’s the Little Things That Add Up to Something Big

As part of the product development team at ARC Audio, Fred, along with the rest of the team at ARC, spends a significant amount of time testing updates that add new features to their PS8Pro digital signal processors. In doing so, this system had to be easily serviceable and updatable so it could be used as one of the several platforms used in evaluating and testing these updates. Along with the DSP’s programing and update capability, there also needed to be update considerations for the non-DSP-equipped third ARC 1000.6 amplifier. To accomplish this, Fred routed three single-piece, 20-foot, low inductance micro-USB cables from the amplifiers to a passive USB hub housed in the depths of the center console to make the process easy.

Another hardwired USB cable runs to the center console compartment from the hub, where a plug with a removable cover was installed to allow Fred to connect his laptop quickly and easily with a single connection without pulling any part of the car apart. For advanced tuning, a second watertight USB port under the vehicle can be used to connect to the processors when a microphone is placed in the driver’s seat.

In case you’re curious, all three ARC A-Series amplifiers can be adjusted using the PS8Pro software for top panel illumination and DSP switching frequency, assuring that the ARC Audio Class-D amplifiers won’t interfere with any of the optional audio sources or OEM electronics. The latter is yet another first-of-its-kind feature and exclusive to ARC Audio.

The USB ports for the Maestro AR modules have also been extended to make them accessible without taking the trim out of the car. The additional USB host ports on the right rear interior panel are nicely tucked away and out of sight to anybody looking in … and out of his kids’ reach, too. This step was crucial to the efficient development of the custom AR software released in late September 2021.

Speaking of the Maestro AR modules and vehicle integration, Fred reprogrammed commands from the bass level adjustment in the radio to act as system subwoofer level control. The speed-dependent volume settings now select from the four system calibration presets he created for the Flex. Preset one is one of Fred’s classic single-seat sound quality configurations with a strong, focused center image. Preset two is similar to the first one, but with more bass and a touch more midbass. Preset three brings in the side and rear speakers for a more immersive experience, but without dramatically affecting the soundstage. Finally, preset four is very immersive. Some people call this an “on-stage” setting, where the music is wrapped around them.

Fred told us that although the Flex wasn’t designed as a show car, the time it took him to integrate everything to a standard he was comfortable with took almost as much time as a build that includes custom-painted fiberglass and edge-lit acrylic panels and accents. In his words, “A lot of work for something that doesn’t look like much was put into it.” We agree that this kind of attention to detail is worth every second.

Fred would like to thank his co-workers at ARC Audio for their ideas, support and assistance while completing this project. He’d also like to thank Dynamat, Stinger, iDatalink, K40 and Firstech for their amazing products. He’d like to thank Chip Foose for influencing the project, and Fred told us he’s looking forward to finishing the paintwork. Finally, and most importantly, Fred would like to thank his better half, Mindy, for green-lighting this latest creation, and his son Fred Jr. for helping bring it together and, most importantly, being part of their first full father/son project.

We want to thank Fred for sharing this fantastic project with the readers of BestCarAudio.com and us. Though we haven’t heard the system in the Flex, Fred is one of the best in the world when it comes to configuring and calibrating automotive digital signal processors. Hearing this vehicle is at the top of our audiophile bucket list.