We are back with the third article in our series about headlight bulb upgrades. In the first article, we discussed the many different headlight bulb designs and how they’ve advanced over the last century. The second article in the series explained the terminology used when discussing light sources. How a light assembly projects light onto the road is more important than the choice of the headlight bulb. If it’s aimed in the wrong direction or with emphasis in the wrong area, you won’t be able to see where you are going. Worse, less-than-ideal light distribution may endanger oncoming drivers. In this third article, let’s review headlight beam patterns.

What Is a Headlight Beam Pattern?

Let’s define the term beam pattern. When you shine a light on a surface, it produces a shape. If the light is a point source like a candle, the light is distributed evenly from the source in the form of a sphere. Bringing the candle up close to a surface will result in a round shape that is brightest, where the light source is closest to the surface. The illumination level decreases as the distance between the surface and the light source increases. Out of a headlight assembly, a halogen or HID headlight bulb effectively acts like a point-source light source.

The results differ if we have a directional light source, like a flashlight. The beam pattern would be a circle on the wall with a sharp cutoff at the edges. The light emanates from the flashlight in the shape of a cone.

Automotive headlamp assemblies are similar to a flashlight. They use a reflector to point the light forward from the front of the vehicle. As forward lighting became brighter, the importance of not blinding oncoming drivers increased. By definition, glare is a harsh, uncomfortably bright light. In the context of our discussion about automotive lighting, glare refers to being subjected to unwanted bright light, typically from another vehicle. An oncoming vehicle’s improperly adjusted lighting system is an excellent example of unwanted glare.

Glare is hazardous as it causes the iris in your eyes to narrow and let in less light. After a vehicle passes you, it takes some time for your iris to open again, making it very difficult to see. Likewise, the bright oncoming light source will drown out darker objects in your peripheral vision. Many advanced driver training courses will suggest that a driver close one eye as a vehicle approaches at night, then open it when the vehicle passes. This process leaves you with one eye ready to see in the dark while the other readjusts. If you’ve seen the movie “Jack Reacher” with Tom Cruise and Robert Duvall, the scene just before the shootout at the mine begins is an example of this technique.

Modern Automotive Headlight Design

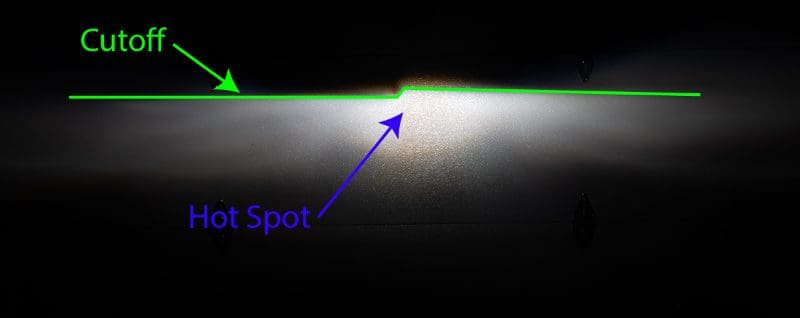

Look at the beam pattern when you drive your car up to a wall or garage door. You’ll quickly realize engineers designed the light to illuminate the road in front of your vehicle without blinding oncoming drivers. What you see will look very different from the flashlight image earlier in this article. Most projector-style headlights have a metal shield between the lens and the reflector that blocks some of the light output. This shield produces a sharp cutoff at the top of the light beam pattern.

It’s logical to think that you could use a simple light that’s aimed lower and avoid all the fancy beam-shaping reflectors and shields. The problem with this configuration is that it puts the brightest part of the light, a location called the hot spot, much closer to your vehicle. You don’t want or need much light in the 20 to 60 feet immediately in front of your car or truck. You want most of the light from your headlights focused beyond 300 feet. This configuration will help provide even lighting in front of the vehicle, especially where the cutoff stops illuminating the road.

Driving Beams and High Beams

So far, we’ve only discussed regular low-beam or driving-beam lighting. Switching on your high beams is quite different. The high beams on your vehicle are nearly identical to a flashlight. They project a cone of light that allows you to see much farther down the road. They typically don’t have a cutoff of any kind.

Modern vehicles typically have three different designs for high-beam lighting. Some use secondary light assemblies with dedicated bulbs. Others use a light bulb with two separate filaments. Finally, many projector-style lights have a cutoff that moves out of the way when the high beams are activated. The shield is driven by a small solenoid when the high beams are activated.

Analyzing Beam Patterns

We set up a projector assembly from a headlight and loaded three different bulbs into it. We took photos of each bulb to compare the beam patterns and light output. We started with a halogen bulb, switched to HID, and finally to two LED bulbs.

As a reminder, we’re analyzing beam patterns and not brightness. That said, in our analysis we must consider where the light energy is the brightest.

All images were taken with a Canon 70D camera using an EF-S 10-22mm F/3.5-4.5 USM lens set to its narrowest 22-mm setting. Exposure was 1/80 of a second with an f-stop of 8 and the camera ISO set to 100. No brightness adjustments were made in post-processing, only cropping.

Starting with the halogen bulb, we can see a very bright hot spot in the middle, just to the right of the cutoff. This brightness pattern works well in illuminating objects several hundred feet ahead of the vehicle. The light output to the sides of the hot spot is reasonable. This lateral lighting would help illuminate objects on the sides of the road or as you’re turning a corner. Light output decreases quickly at the bottom of the pattern. This foreground performance helps prevent a bright spot immediately in front of the vehicle.

Moving to the HID bulb, we see a larger diameter hot spot in the middle of the image. This light distribution pattern isn’t as ideal as the halogen bulb. The horizontal performance with the HID is good. You can see some slight unwanted reflections above the cutoff, but they aren’t bad. Finally, the foreground performance looks to be similar to that of the halogen.

Next, we have the ATOM LED bulb in this projector application. This bulb has less of a hot spot, so the light distribution appears relatively even through the illuminated area. One benefit is this LED bulb is that the cutoff is very abrupt. There is little to no light above the cutoff so that oncoming drivers won’t experience as much glare.

Finally, we have the Lumens Sportline bulb. This bulb has a large hot spot in the middle and maintains the sharp cutoff of the ATOM bulb. This bulb puts much more light on the road than the ATOM but is a bit bright in the foreground.

The halogen and HID bulbs significantly outperform the LED bulbs in this application. Keep in mind that this is a specific projector assembly. Further, our research shows that it’s not the highest-quality design available. A differently shaped projector or a reflector-style lighting assembly would likely produce very different results. The takeaway is that your installer needs to experiment with different options to ensure that you get a genuine upgrade for your light bulb investment, not just a different color bulb.

Dangerous Beam Patterns

It’s often difficult to know what to look for in a beam pattern without knowing when something is wrong. Here are some random examples of undesirable headlight beam patterns we found online.

A quick analysis of the above image shows several issues with the left-side headlight of this BMW 330i. There is a dark spot in the middle of the pattern. The lack of light in the center would dramatically reduce long-distance visibility. There is also too much light at the very bottom of the pattern. Too much light down low illuminates the area immediately in front of the vehicle too much. The result is another reduction in long-distance visibility. The left headlight is also aimed higher than the right. Improper aiming results in blinding oncoming drivers or poor long-distance visibility.

Based on a quick analysis of the above image, someone has likely installed incorrect bulbs in this Subaru Outback or clocked them incorrectly. There is a poor cutoff, minimal lateral light distribution and far too much light in the foreground. Given the distance to the garage door, we’d also predict that the right-side headlight is aimed much too far to the left. Driving with a lighting system that performs like this could be very dangerous.

Though the actual light pattern from this 2014 Lexus ES isn’t bad, the headlights need proper aiming. The right headlight is probably aimed too high. The rectangles above the cutoff are intentional and illuminate street signs.

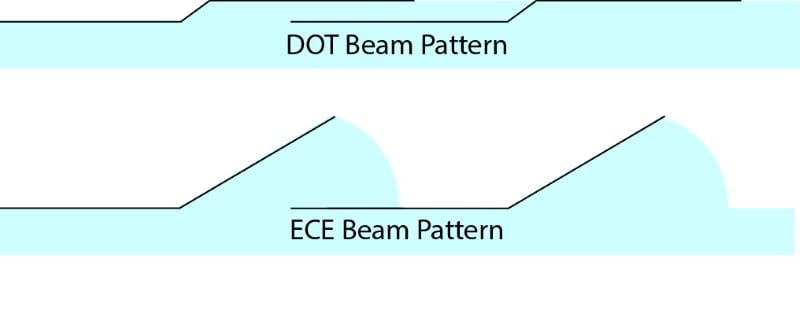

North American and European Lighting Standards

The guidelines for automotive headlights differ significantly between Europe and North America. If you look at the light patterns we’ve shown, there is a clear step in the middle of the pattern. The left side is lower than the right. This pattern provides better road illumination in the front of the vehicle with less chance of blinding an oncoming car or truck. In Europe, rather than a step, the cutoff is at an angle that extends to the edge of the assembly. This pattern illuminates more of the road and increases light to the right-side shoulder. This design would work better to light up road signs.

Proper Forward Lighting Is Crucial to Safe Night Driving

If you’ve changed or upgraded your headlights or are planning to, this article explains the importance of choosing headlight bulbs or light assemblies that work correctly. A high-output bulb in an incorrect application can drastically reduce how well you can see. Work with a specialty mobile enhancement retailer to pick only the best solutions for your application. Improving nighttime visibility may require testing different bulb options in your vehicle. We’ll discuss light color and brightness in our next article.