Bass reflex speaker enclosures are extremely popular options for car audio subwoofer systems. These enclosures dramatically increase low-frequency output compared to acoustic suspension enclosures without the need for more power from an amplifier. They also reduce the subwoofer’s excursion requirements at low frequencies. There are some essential vent design criteria to consider when shopping for an enclosure. We aren’t going to discuss selecting a tuning frequency and how it affects frequency response or power handling.

What is a Bass Reflex Subwoofer Enclosure?

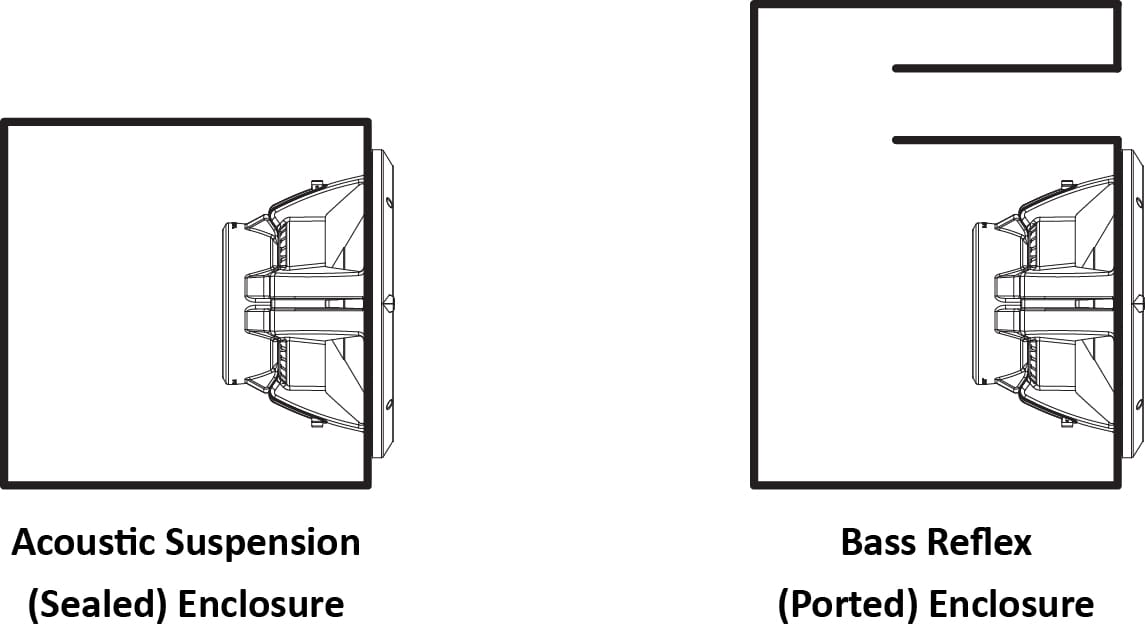

Let’s get a few definitions out of the way first. The simplest subwoofer enclosure is called an Acoustic Suspension design. Often called sealed enclosures, they are simply cabinets with a specific volume and no features other than a hole to mount the subwoofer. A bass reflex subwoofer enclosure, often called a ported or vented design, adds a feature like a tube or slot that is open at both ends. This tube has a specific area and length, so the air inside resonates at a particular frequency. Bass reflex enclosures are typically larger than an acoustic suspension design but offer an increase in output of roughly six dB around the vent’s resonant frequency. This is called the tuning frequency.

Vent Area Matters

One of the most important considerations when picking a subwoofer enclosure is to ensure the vent is large enough. Many factors go into selecting the vent’s area, including the subwoofer’s effective cone area, the subwoofer’s excursion capabilities, the net volume of the enclosure, the tuning frequency of the vent, and how much power you have available from the amplifier.

If a vent is too small, the air inside will move too quickly and cause noise. These vent noises are often called chuffing, huffing, or turbulence. While there is a range of acceptable vent air velocities, a good guideline is to keep them under 10% of the speed of sound, which is 34.3 meters per second. This is the upper limit suggested by BassBox Pro, the subwoofer enclosure simulation software we use most frequently. Based on the hundreds of enclosures we’ve constructed using data from this software, the simulations are very accurate.

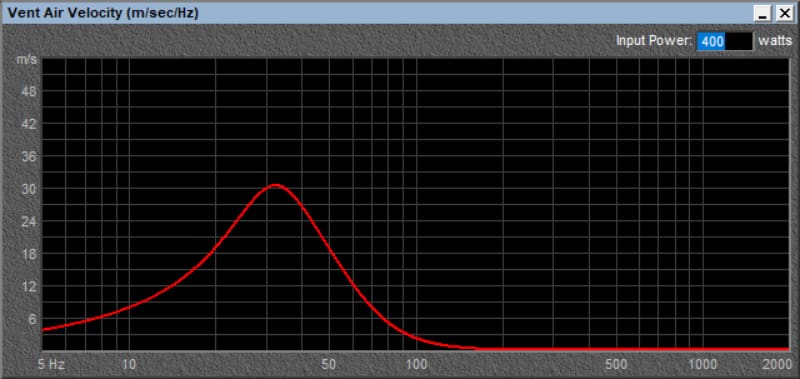

So, let’s look at some vent velocity simulations. We’ll use the Rockford Fosgate P2D2-12 subwoofer as an example. We reviewed this subwoofer recently, and it performs magnificently. We’ll use the 1.79 cubic foot enclosure that Rockford Fosgate recommends and a 4-inch diameter vent tuned to 40 Hz. The simulation below shows vent velocity versus frequency with the driver driven with its rated 400 watts.

The graph shows that at around 32 hertz, the velocity of the air resonating in the vent will reach a maximum of 30.5 meters per second (m/s). This is a good maximum velocity, and the vent should function well.

Vent Area Versus Velocity

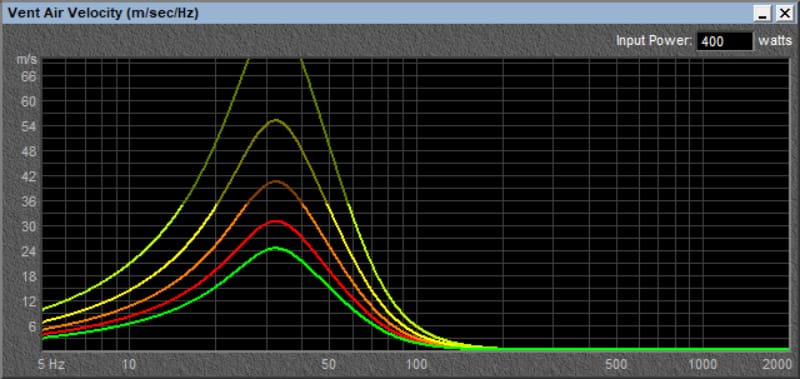

Now, let’s show what happens to vent velocity if we change the area and adjust the length to maintain the same 40 Hz tuning. The orange trace in the graph below represents a 3.5-inch diameter vent. The yellow trace is a 3-inch vent. The lime green trace is a 2.5-inch vent. Finally, the bright green trace at the bottom of the graph is a 4.5-inch diameter vent.

It’s easy to see that the air velocity increases with smaller area vents and decreases with larger vents. What’s crucial to bass reflex enclosures is the mass of the air that’s resonating. The vent is not a “hole” that sound comes out of, like a faucet that allows water to drain from the tank. A column of air moves up and down in the vent, like the piston in a car engine.

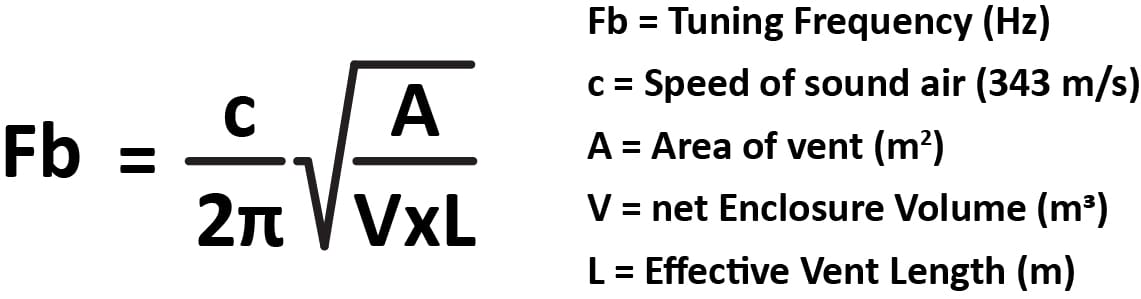

The formula that determines the vent tuning frequency is shown below:

Looking at the above equation, an increase in the vent area will raise the tuning frequency for a given enclosure volume and vent length. Increasing the enclosure volume for a given vent area and length will decrease the tuning frequency. Likewise, increasing the vent length for a given vent area and enclosure volume will decrease the tuning frequency.

Subwoofer Size Affects Vent Requirements

Vent velocity also depends on the size of the subwoofer used in the enclosure. An 8-inch woofer might only need a 2.5-inch vent. Our 12-inch P2D2-12 works well with a four-inch vent. A monster subwoofer like the 16-inch Rockford Fosgate T2S1-16 needs a seven-inch diameter vent.

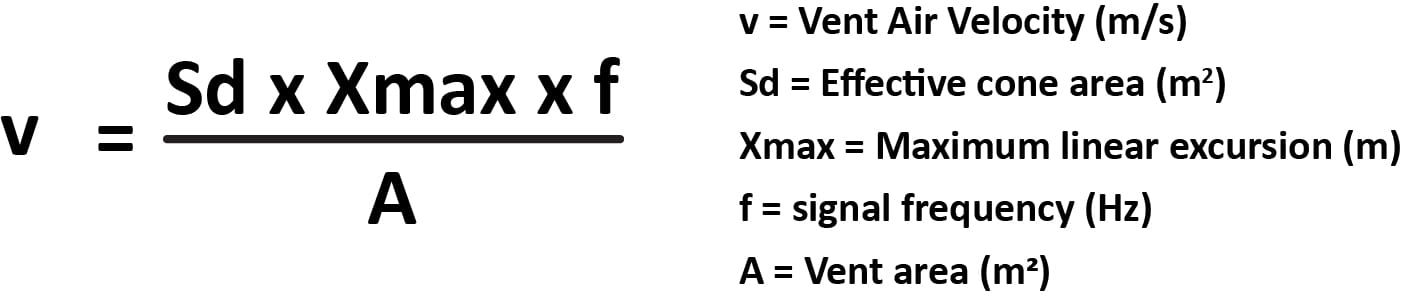

The formula to calculate vent velocity is:

As you can see, increases in effective cone area, driver excursion, and frequency will increase vent velocity. Decreases in vent area will decrease velocity. This formula doesn’t tell the whole story, as cone excursion also depends on frequency. As such, the math is much more complicated than we will get into here.

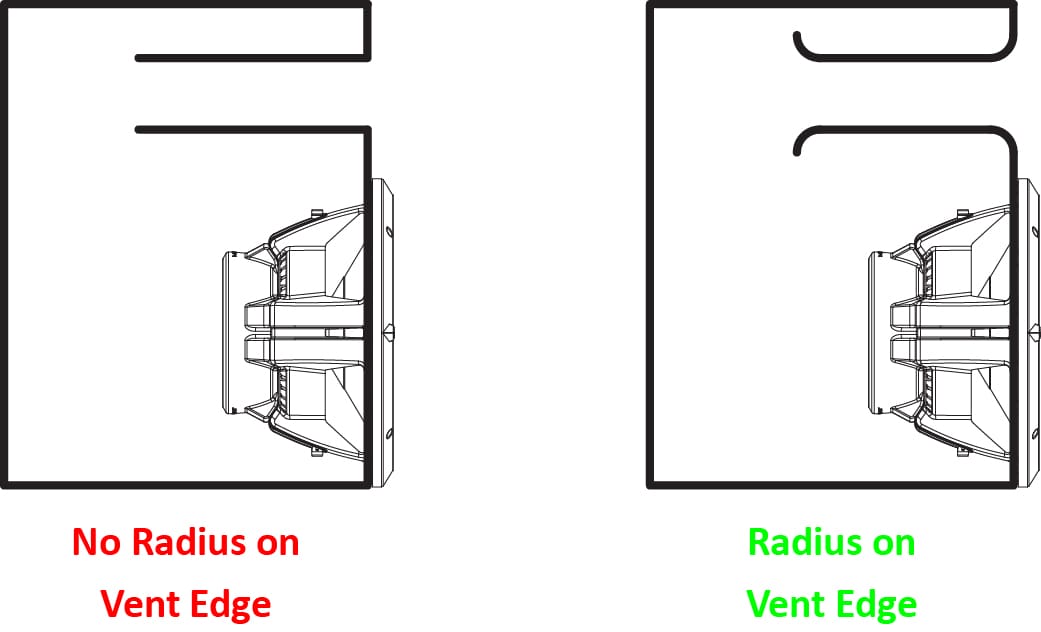

Flared Vents Can Reduce Noise

A poorly designed vent will cause audible noise, which we can consider a type of distortion. The enclosure designer will want to minimize noise to deliver a subwoofer solution that sounds good. Adding a radius to the edge is one way to improve a vent’s performance. These are often called flared ports or vents.

Vent Physical Considerations

In the 1980s, when most of our team started learning about designing car audio subwoofer enclosures, we were introduced to clear guidelines regarding the vents’ size and physical location in an enclosure.

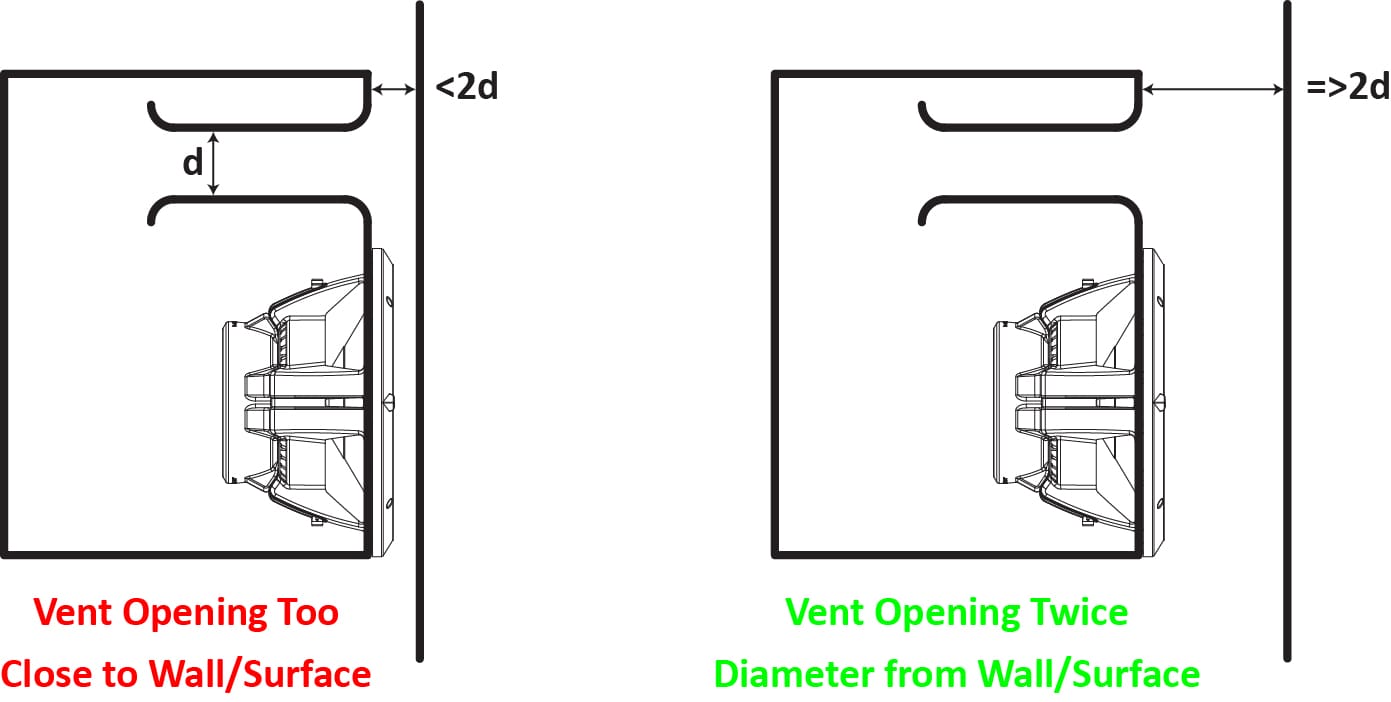

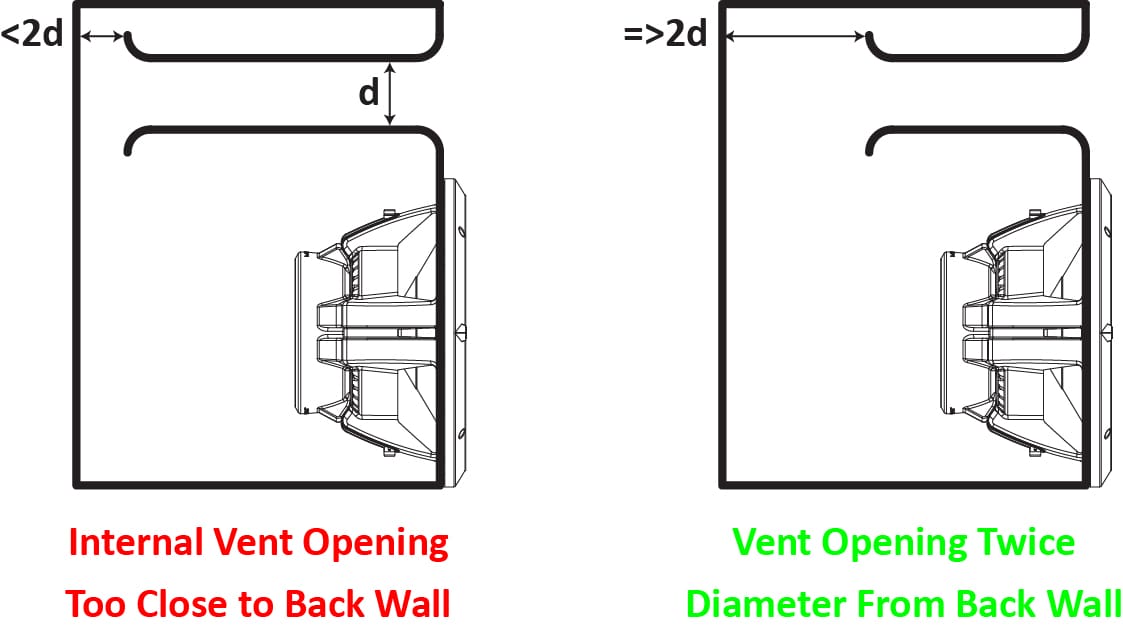

Testing by Vance Dickason (Author of the *Loudspeaker Design Cookbook*) shows that if the vent opening (inside or outside of the enclosure) is within three inches of a surface, the effective tuning frequency at higher output levels will be affected. Going back to the 80s, we were taught that the vent should be no less than twice its diameter from any perpendicular surface. This applies to both the inside and outside of the enclosure.

Vent Design Observations

The engineers at Harman International (the company that owns JBL and Infinity) have extensively tested all types of subwoofer and speaker enclosures. With respect to vent design, here is a list of some of their findings. The source is *The Loudspeaker Design Cookbook* by Vance Dickason.

- Flared ports exhibit less power compression than straight ports.

- Port tuning of flared ports is only slightly dependent on flare and primarily dependent on the minimum diameter and the total length of the port.

- Resonance increases as ports compress, likely attributed to the effective length of the port decreasing as turbulence increases.

- Extremely flared ports show more compression and distortion at maximum SPL levels than more moderate flared ports, suggesting that a compromise between the two is desirable.

- Roughness of the interior vent surface appears irrelevant in port function.

- Asymmetrical inlet and exhaust ports with a shallow radius on the inlet end and a larger radius on the exhaust end provide the best balance of lowering distortion and compression.

Based on observation one, adding a flare to the edge of a vent will reduce noise and improve performance. Interestingly, observation six extends this guideline by suggesting that the flare inside the enclosure should have a smaller radius than the outside.

Vent Length and Shape Considerations

Designing a subwoofer enclosure can be tricky. Say you have a single 10-inch driver and want your installer to create a relatively small vented enclosure that plays loudly at low frequencies. They will often find that the area and length of the required vent makes it very challenging to construct. A one-cubic-foot enclosure tuned to 31 hertz technically requires a vent that is just over three inches in diameter. The vent must be 17.125 inches long to achieve the target tuning frequency. It’s not easy to fit that long vent into most designs. Further, observation three from above warns against using exceptionally long vents. Simulating an enclosure in software that isn’t practical to construct is easy.

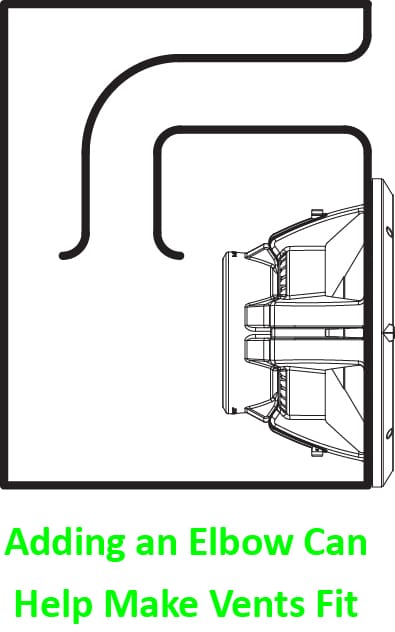

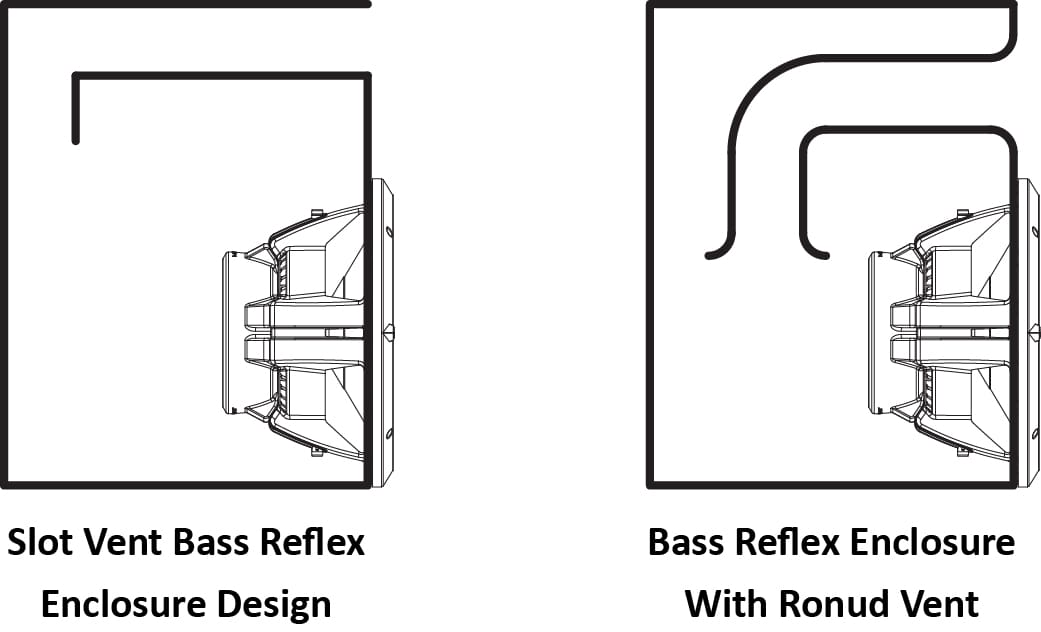

One solution for long-vent requirements is to add an elbow to a round vent. This will let your installer position the vent’s opening away from nearby enclosure surfaces. The elbow will also allow the vent to fit better into the cabinet.

Another popular option is constructing a wood vent, often called a slot port. These are reasonable solutions for applications with relatively long vent length requirements and large vent areas.

Issues with Slot Vents

“However, slot vent designs come with certain drawbacks. In terms of internal surface area, which correlates with aerodynamic resistance, a circle provides the smallest circumference for a given area. For instance, a 4-inch diameter round vent has a circumference of 12.56 inches. In contrast, a slot port measuring one inch by 12.56 inches offers the same area but results in an effective circumference of 27.12 inches. This increased surface area can create turbulence, thereby reducing the vent’s effectiveness. Consequently, squarer vents are generally more efficient than long slots.

Additionally, another potential issue arises when failing to add a radius to the end of the slot vent. Many poorly designed enclosures do not make any effort to smooth the transition of a slot port to the enclosure face, leading to potential noise issues.

Shopping for a Subwoofer Enclosure

If you are having a subwoofer enclosure constructed for your vehicle, discuss these design elements with the installer. If you are shopping for an off-the-shelf enclosure, aside from having the shop simulate the response of the driver(s) you are using, make sure it also follows these basic design guidelines. The vents should have a radius on both ends. They should end well away from any other internal panels. The inlet of the vent should be smooth and without obstruction.

Choosing a subwoofer enclosure that follows these vetn design guidelines will help ensure your car audio system sounds great and performs reliably for many years. Visit a local specialty mobile enhancement retailer today to learn about the subwoofer upgrades available for your vehicle.